Pipe Prefabrication

Under Control.

Boost productivity, reduce waste, and gain real-time visibility — all with software that connects your entire pipe prefabrication process.

Smarter Pipe Prefabrication Starts Here

PipeCloud helps pipe prefabricators and shipbuilders gain control over their operations by replacing manual, disconnected workflows with one digital system.

What Industry Leaders Say About PipeCloud

Hear directly from the pipe fabricators and shipyards using PipeCloud to scale production and improve efficiency.

What is PipeCloud?

PipeCloud is intelligent software that streamlines pipe prefabrication by automating routine tasks and supporting teams with the tools they need to perform at their best.

Manual planning, repetitive data handling, and error-prone processes slow down production and waste valuable resources. PipeCloud replaces these with automated, reliable workflows — helping you get more output from the same machines and people.

From extracting material data to assigning work orders and tracking progress in real time, PipeCloud connects the entire production chain into one system, improving productivity across the board.

How Does PipeCloud Work?

Pipe prefabrication has traditionally relied on manual planning, paper documents, and disconnected tools. PipeCloud changes that by digitalizing the entire process in one connected system that automates planning, coordination, and tracking from start to finish.

Got questions?

We’re here to help.

Your questions matter. Drop us a line anytime. We’ll get back with the details you need.

Key Benefits for Pipe Prefabricators

PipeCloud helps pipe prefabricators foster competitive advantage by automating repetitive tasks, improving visibility, and unlocking more output from the same resources.

1 Real-time production visibility

2 Less manual work

3 Smarter capacity planning

4 More accurate bidding

5 Higher machine utilization

6 Digital weld traceability

7 Less material waste

8 More consistent shop floor execution

9 Subcontractor management

10 No complex IT setup required

PipeCloud Featured in Industry Media

USA Today

USA Today

The Outfitting Constraint in Shipbuilding

PipeCloud was recently featured in a USA Today article examining shipyard throughput and productivity challenges in modern shipbuilding. The article includes insights from PipeCloud CEO and Co-Founder Jarno Soinila on the growing gap between digitally mature hull construction and slower, fragmented outfitting operations.

Douglas Magazine

Douglas Magazine

Coverage of Seaspan’s New Facility

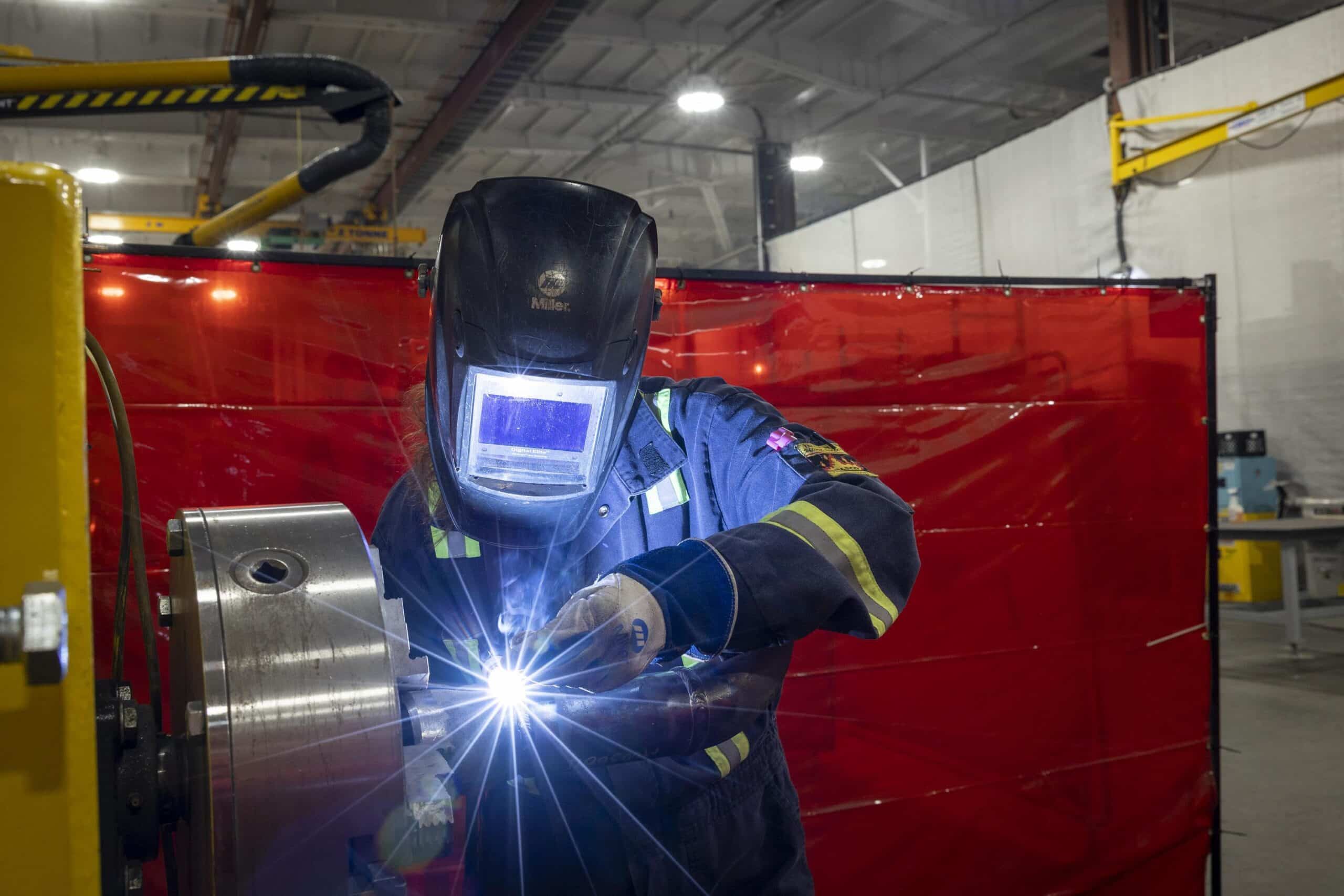

PipeCloud was featured in Douglas Magazine as part of an in-depth article covering Seaspan’s new pipe-spool prefabrication facility at Ark Road near Shawnigan Lake, British Columbia. The article highlights how Seaspan is modernizing pipe prefabrication by combining robotics, centralized production, and digital workflows to support major shipbuilding programs.

Taking The Paper Out of Piping: Rebuilding the Industry

We’re proud to share that PipeCloud has been featured in the International Business Times for transforming how the pipe prefabrication industry works — moving it from paper-based processes to a fully digital, data-driven future. The article highlights how PipeCloud helps shipyards and fabricators eliminate manual workflows, increase productivity, and gain real-time visibility across production.

Built for Pipe Shops, Shipyards, and EPC Companies of All Sizes

PipeCloud is designed for pipe prefabrication teams of all sizes across the industry — from growing workshops to large shipyards and EPC companies managing complex projects. By replacing manual tasks and disconnected tools with one connected system, PipeCloud helps you cut costs, reduce waste, and boost productivity. With flexible pricing packages and no complex IT setup, PipeCloud is a cost-efficient solution that delivers real impact — whether you’re just starting to scale or coordinating thousands of spools across multiple sites.

Jarno Soinila

CEO

Strategy, Partnerships, Sales Development

Vertti Siivola

Technical Solutions Specialist

Sales, Implementations, Customer Success