Production Welding Processes That Optimize Pipe Spool Fabrication

Discover production welding processes that streamline pipe spool fabrication. Learn techniques, challenges, and innovations to optimize your workflow.

PipeCloud offers a multitude of tools for quality assurance. With PipeCloud you can create a separate inspection work order, use the user customizable meta fields at welding work order to record welder performed quality checks.

Welding quality is perhaps the most important aspect of pipe prefabrication. Imagine the panic, if the weld seams are spot checked with X-ray at the installation site and 10% of the welds are faulty. Then the customer demands a full 100% X-ray’s to be taken and you end up paying for that and re-do at the site 10-30% of the welds!

Luckily PipeCloud offers a multitude of tools for quality assurance. With PipeCloud you can create a separate inspection work order, use the user customizable meta fields at welding work order to record welder performed quality checks or you can use the WeldEye software integrated to PipeCloud to manage WPS’s among other things.

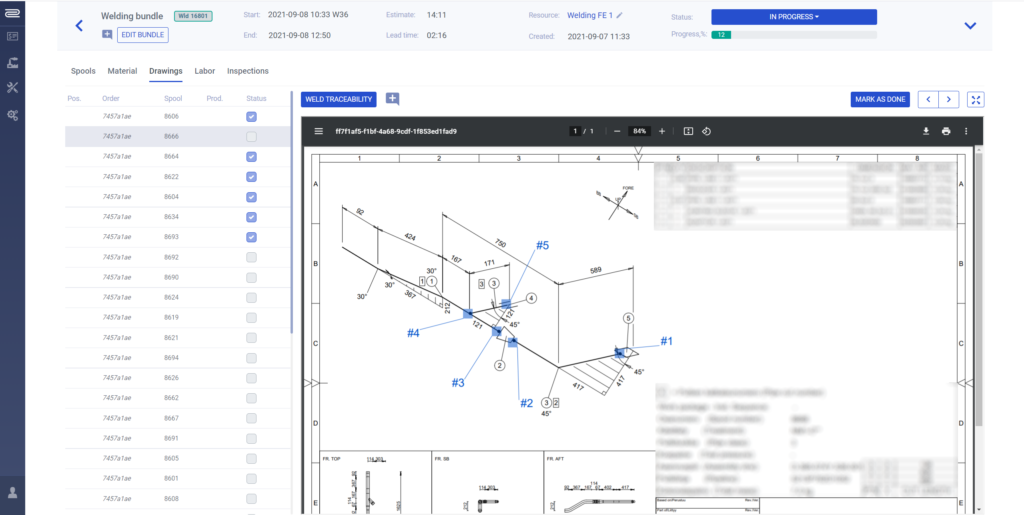

After the fitter has spot welded the components together, it is time for the welder to start working. PipeCloud informs welder in the welding bundle view the required weld type, possible traceability requirements and QA inspection needs.

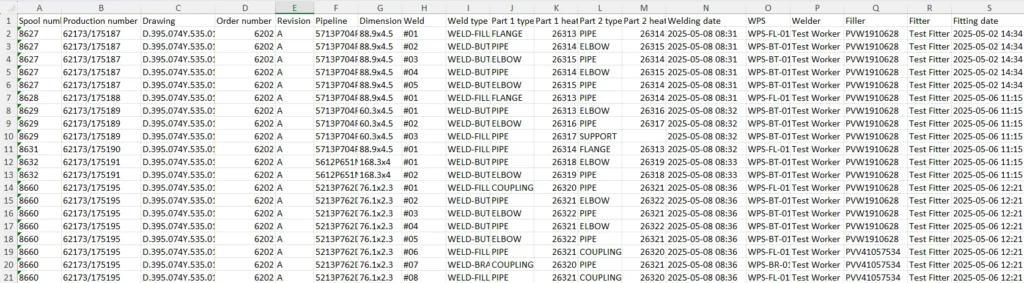

The welding traceability can be entered by the welder in the welding bundle view. Alternatively welder can use WeldEye by Kemppi for WPS management and traceability data collection. PipeCloud has integration with WeldEye and can send the welding work orders to WeldEye.

Your questions matter. Drop us a line anytime. We’ll get back with the details you need.

Discover production welding processes that streamline pipe spool fabrication. Learn techniques, challenges, and innovations to optimize your workflow.

Learn how welding traceability software improves project management with real-world examples from shipbuilding, energy, and manufacturing industries.

Welding traceability made easy. PipeCloud’s feature lets you log, trace, and report welds instantly. Reduce rework, ensure compliance, and catch issues early.

Ensure quality and compliance in piping projects with welding traceability. Learn its importance, challenges, and modern solutions to streamline processes.

Discover how Ideal Welders and PipeCloud enhance precision and efficiency in pipe fabrication processes through advanced technology.

Learn the complete pipe fabrication workflow, from design to assembly. Look into processes, components, best practices, and modern innovations in fabrication.

“You can easily see that all the preconditions are ready for fitting. PipeCloud shows you the status of all the previous work phases, so you don’t have to run around the factory with papers”

Digitalization of welding accelerates when the capability of the most intelligent welding machines is combined with the information produced by a unique manufacturing execution system …