Pipe Bending Calculator: Essential Tool for Accurate Fabrication

Discover how a pipe bending calculator simplifies fabrication with precise parameters for bend allowance, radius, and material considerations. Save time and reduce waste!

Bending a pipe saves significant fitting and welding work. Each bend usually saves 2 weld seams.

Bending a pipe saves significant fitting and welding work. Each bend usually saves 2 weld seams. So it really makes sense to utilize bending when ever it is possible.

The most challenging task in bending is the calculation of the bending coordinates. This requires either a very experienced bending machine operator or a skilled engineer for offline calculations. In both cases human errors unfortunately tend to happen and the cost savings in bending are lost.

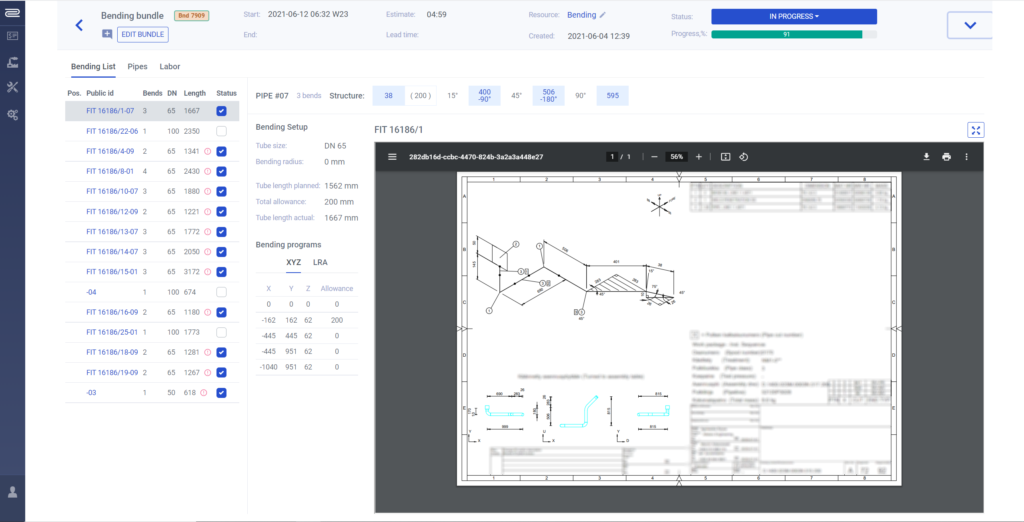

PipeCloud has bending program calculator that automatically calculates the bending coordinates / programs. For this automatic function PipeCloud needs two preconditions:

On the picture is an example bending bundle (work-order)

When working with unique pipe prefabricates the setup time can be the biggest portion of time needed for bending. Usually the setup time is needed when the diameter or the wall thickness of the pipe changes.

PipeCloud’s solution to utilize bending as an independent sub-process enables combining multiple orders bended pipes with same characteristics to a work-order minimize the setup time significantly.

Your questions matter. Drop us a line anytime. We’ll get back with the details you need.

Discover how a pipe bending calculator simplifies fabrication with precise parameters for bend allowance, radius, and material considerations. Save time and reduce waste!

Learn the complete pipe fabrication workflow, from design to assembly. Look into processes, components, best practices, and modern innovations in fabrication.

Learn essential pipe bending techniques and best practices for precision. Master mandrel, rotary draw, compression, roll, and heat induction bending efficiently.

“You can easily see that all the preconditions are ready for fitting. PipeCloud shows you the status of all the previous work phases, so you don’t have to run around the factory with papers”