What is Pipe Prefabrication?

Pipe prefabrication means manufacturing pipeline sections in a workshop instead of on the construction site. This approach allows the use of better tools and controlled working conditions. As a result, productivity increases, quality improves, and on-site installation time is reduced.

The Challenge of Uniqueness

Each prefabricated pipe spool is typically one of a kind. As a result, pipe prefabrication workshops produce a high volume of unique products rather than large quantities of identical ones. This production model makes generic manufacturing execution systems (MES) poorly suited for the job. Instead, pipe prefabrication requires a purpose-built system designed specifically for this type of work.

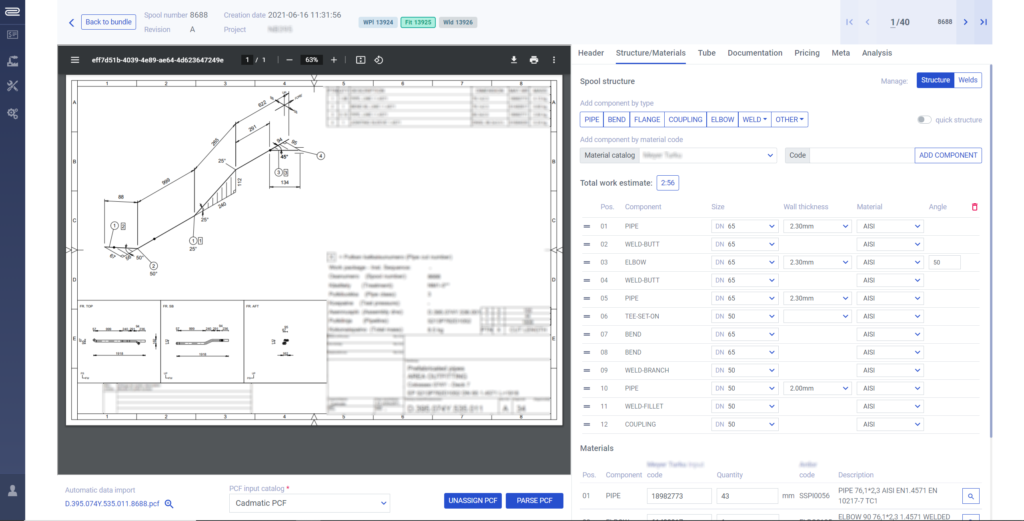

PipeCloud solves this challenge by automatically extracting the spool structure and required work phases from isometric drawings, specifically from PCF files. PCF is a standard export format used by most 3D piping design CAD systems.

From Engineering to Execution

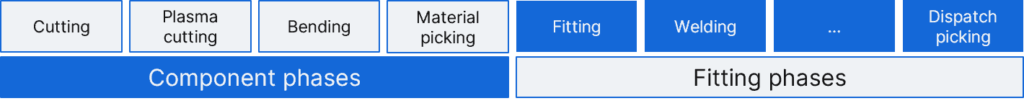

Pipe fabrication can be divided into independent sub-processes, which allows workshops to apply serial production methods even when producing one-off spools. These work phases fall into two main categories:

- Component phases such as cutting, bending, plasma cutting, and material picking

- Fitting phases which involve tasks at the spool level, like fitting, welding, and dispatch preparation

Each of these phases requires different types of information. PipeCloud automatically extracts all necessary data from isometric drawings and engineering metadata, enabling accurate planning and streamlined execution across the entire workflow.

-

Bending

Bending a pipe saves significant fitting and welding work. Each bend typically eliminates the need for two weld seams. -

Cutting

Cutting is usually the first work phase needed in pipe prefabrication. PipeCloud creates the work order automatically for the selected spools that require cutting. -

Fitting

Fitting is the phase where all prefabricated components are assembled into a complete spool. This is the first production step that focuses on the entire spool, rather than individual parts. -

Plasma cutting

Plasma cutting is typically used for beveling pipe ends for welding and for cutting branch holes. -

Welding

PipeCloud offers a range of tools for welding quality assurance. You can create separate inspection work orders or use customizable meta fields to log quality checks during welding.