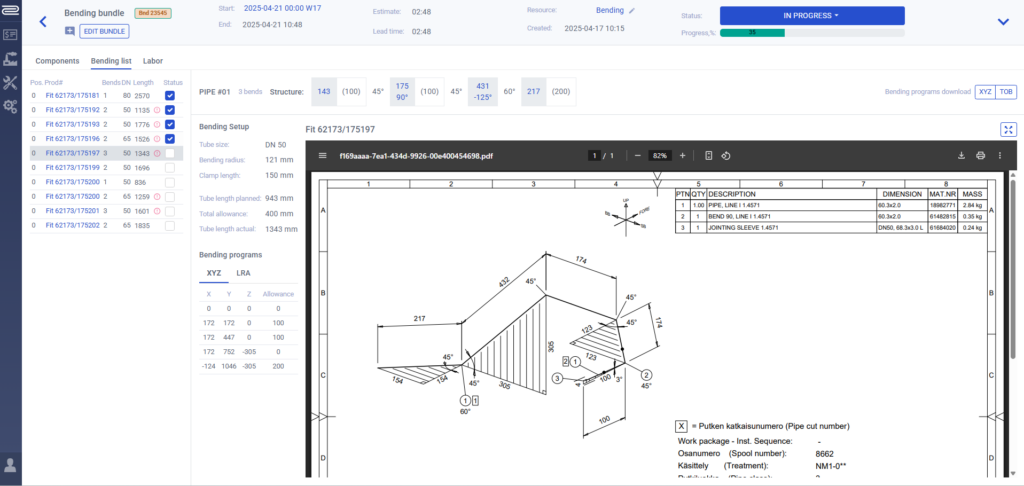

Automatic bending programs

Generate and download machine-ready bending programs based on spool geometry and your bending machine setup — no manual calculations needed.

Pipe prefabrication has traditionally relied on manual planning, paper documents, and disconnected tools. PipeCloud changes that by digitalizing the entire process in one connected system that automates planning, coordination, and tracking from start to finish.

Generate and download machine-ready bending programs based on spool geometry and your bending machine setup — no manual calculations needed.

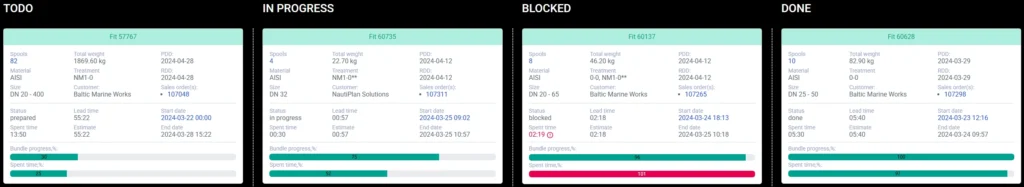

PipeCloud’s Kanban view shows the live status of every production task. Quickly see what’s in progress, blocked, or falling behind without spreadsheets or shop floor walkarounds.

Live factory view gives you a real-time, 3D overview of your own production floor. See active workspaces, track bundle progress, and understand what’s happening and where — without stepping into the shop.

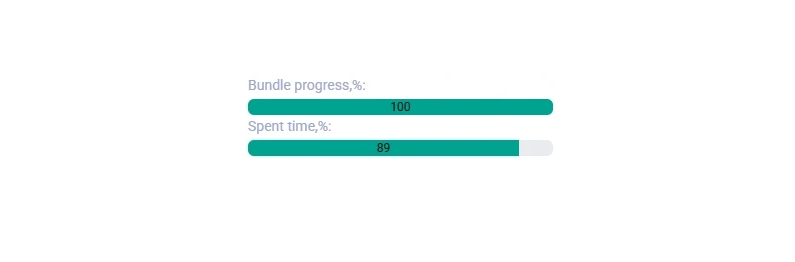

Track real-time progress and spent time across every production phase. Compare estimates with actuals, identify delays early, and bring full transparency to your pipe prefabrication workflow.

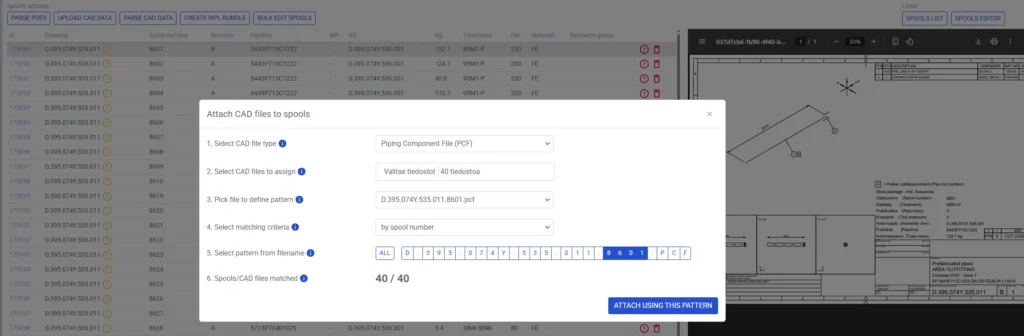

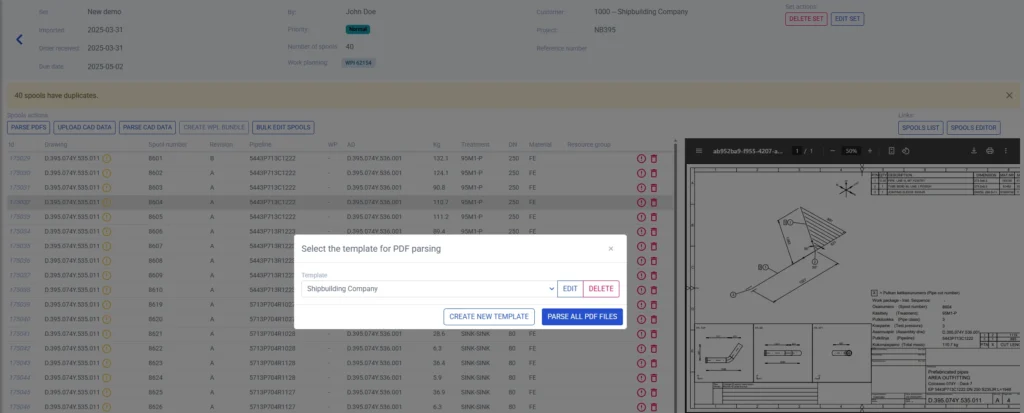

Automatically parse PCF and XML files to extract CAD data and connect it with spool drawings. PipeCloud turns raw design data into structured spool information ready for digital planning and production.

Automate spool information gathering. Upload PDF drawings, extract key spool data automatically, and skip the manual entry. Fast, accurate, and ready for planning.

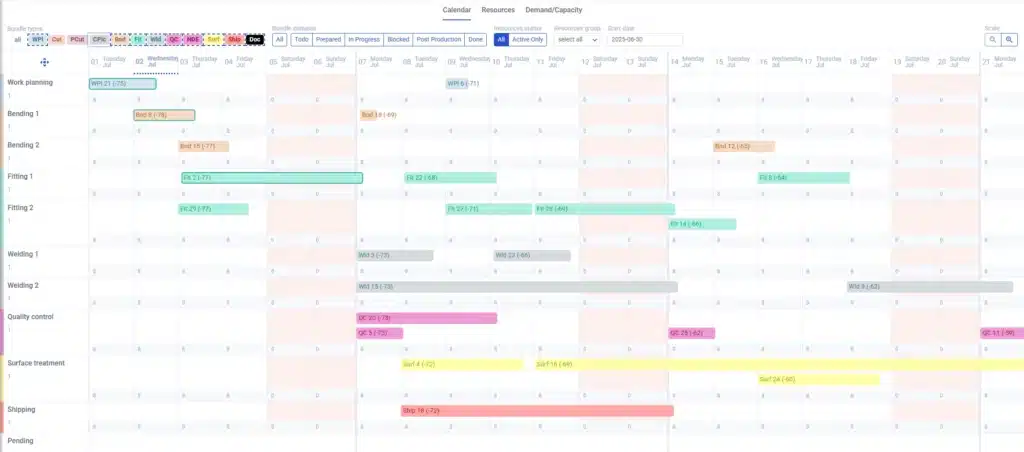

PipeCloud’s capacity planning helps you balance shop floor resources, assign tasks with precision, and plan production efficiently. Gain real-time visibility to avoid bottlenecks and keep schedules on track.

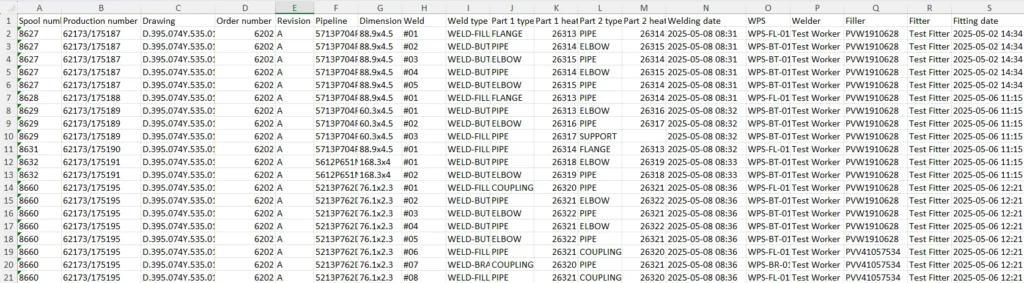

Welding traceability made easy. PipeCloud’s feature lets you log, trace, and report welds instantly. Reduce rework, ensure compliance, and catch issues early.