Customers

Hear how pipe fabricators and shipyards use PipeCloud to improve pipe fabrication

What Industry Leaders Say About PipeCloud

Hear directly from the pipe fabricators and shipyards using PipeCloud to scale production and improve efficiency.

Doubling pipe spool output at Seaspan

By integrating PipeCloud’s technology within our current preproduction process, we believe we will achieve significant improvements in production efficiency and precision.

50 pipes in 10 minutes at Damen Naval

We would use various Excel sheets to create things like material lists or spool lists. Now with PipeCloud, we can do everything automatically. It takes about 10 minutes to prepare delivery packages for 50 pipes.

Precision, speed, and control at Helsinki Shipyard

Partnering with PipeCloud helps us future-proof our prefabrication processes, delivering precision, speed, and control that are essential for our large-scale projects and growth.

Real-time insight at Ideal Welders

The integration of PipeCloud marks a turning point for our operations. This level of real-time insight and efficiency equips us to deliver even greater value to our clients

Full welding traceability at Ardor

In PipeCloud, every action is tracked. This is extremely beneficial if there is a customer claim for welding. I don’t have to guess who welded that particular pipe; I can see it directly in PipeCloud.

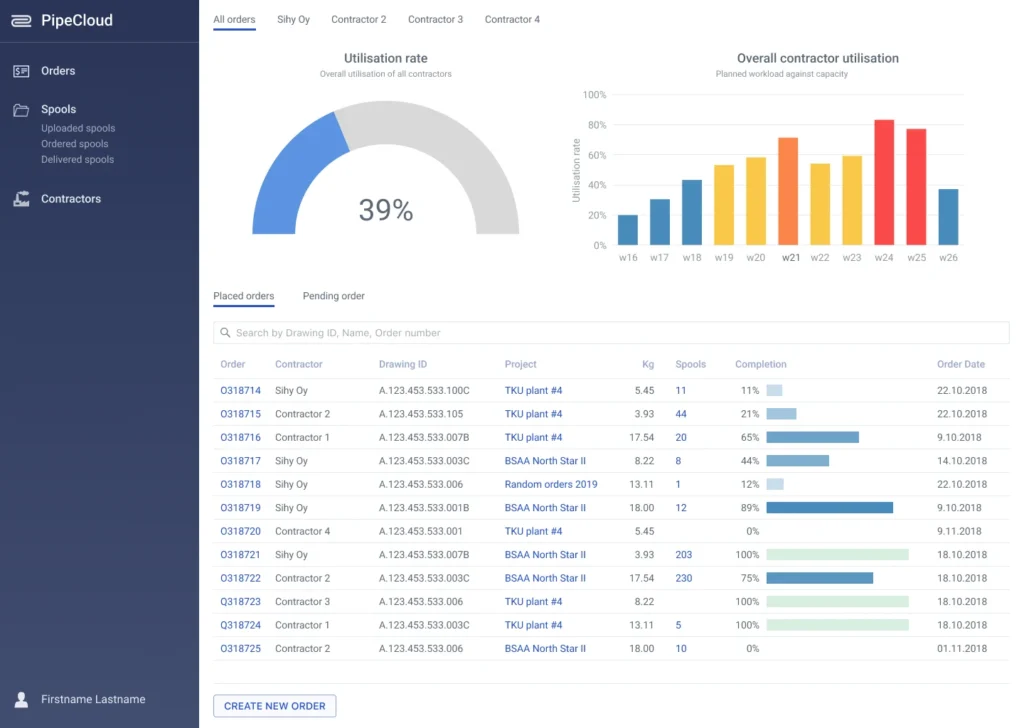

Efficient resource planning at Ulstein

We needed to renew the software and re-plan the pipe shop here at Ulstein. The software we were using was out of date and didn’t have the resource planning that the PipeCloud software offers.

Automatic delivery packages at Damen Naval

All we have to do is click and drag the PDF and PCF into PipeCloud. And then PipeCloud generates the delivery package, containing all the information that a pipe-fitter needs.

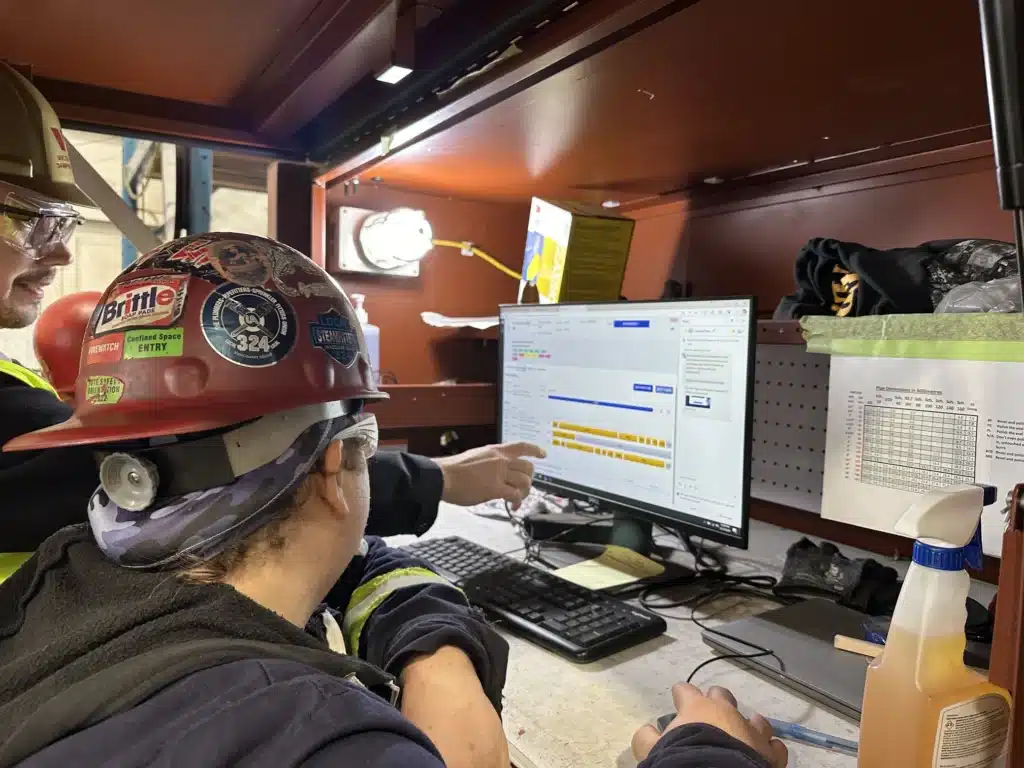

Production data in your pocket at Ardor

All the necessary production information is available on my smartphone via PipeCloud. This means that all the issues that come up during the day can be clarified within seconds.

Full production oversight at Damen Naval

This is now so straightforward. PipeCloud’s to-do list and calendar gives us this oversight, showing exactly what has been done and what still needs to be done.

Case Studies

Learn how fabricators and shipyards use PipeCloud to simplify the entire pipe prefabrication process. From preparing work to tracking progress and proving quality, these stories show how a unified software system helps piping teams move faster with fewer interruptions.

Seaspan Doubles Pipe Spool Output

Problem

Seaspan’s outdated processes and rising production demands

To support the Canadian Coast Guard’s new Polar Icebreaker and future vessels, Seaspan needed to modernize its pipe spool production.

Solution

PipeCloud to digitize and streamline pipe prefabrication operations

- Digital workstations replaced paper-based workflows

- Automated planning and CNC generation from PCF/PDF

- Real-time tracking and shop-floor coordination.

Result

Enabled a scale-up from 4,500 to 9,500-10,000 pipe spools/year

- Helped Seaspan scale output and prepare for large-scale builds

- Reduced manual coordination across teams with paperless production

- Improved traceability, visibility, and real-time control.

Faster Work Packages at Damen Naval

Problem

Manual prep slowed down engineering-to-production handoff

Piping teams relied on various Excel sheets and legacy tools to manually generate work orders, including cutting lists, material lists, and bending programs.

Solution

PipeCloud for end-to-end automated manufacturing engineering

- Drag-and-drop import of pipe drawings (PDF) and component files (PCF)

- Auto-generated all-in-one pipe delivery packages: Work tasks, optimized cutting lists, bending programs, spool & material lists

- Centralized tracking and planning for pipe production.

Result

Improved speed, accuracy, and coordination across pipe production

- Reduced prep time to 10 minutes for 50-pipe spool delivery packages

- Enabled real-time planning and status visibility across pipe production operations

- Standardized, digital handover materials for collaboration with partner shipyards.

Ardor Goes Paperless on the Shop Floor

Problem

Paper-based workflows slowed handoffs and made tracking difficult

Foremen spent time distributing work orders, chasing status from multiple people, and resolving blocked tasks without clear visibility to materials or prior phases.

Solution

PipeCloud paperless production for real-time visibility and assignment

- Work orders assigned in-app to each worker’s “My bundles” view

- Live phase status to confirm fitting prerequisites before starting

- Touchscreen reporting for blocked work (missing materials auto-routed to warehouse)

- Smartphone access to drawings, tasks, and traceability in seconds

- Semi-automatic scheduling by delivery dates to keep priorities clear

- Automatic QA and heat-number reporting

Result

Faster handoffs, fewer interruptions, and clearer ownership on the floor

- QA documentation effort reduced from 1–2 days to an automatic report

- Misplaced drawings eliminated with digital work orders

- Easier reassignment when someone is absent, since status is visible in real time

- Foreman time freed for continuous improvement instead of paper distribution and manual chasing

- Full weld and operator traceability available instantly for customer claims and internal reviews

Got questions?

We’re here to help.

Your questions matter. Drop us a line anytime. We’ll get back with the details you need.

Customer News

PipeCloud Selected by Helsinki Shipyard to Drive Digital Transformation in Pipe Prefabrication

PipeCloud has been selected by Helsinki Shipyard to modernize pipe prefabrication with a digital platform. The partnership strengthens Helsinki’s shipbuilding capabilities as production scales under Davie ownership, combining heritage expertise with real-time visibility, advanced planning, and improved efficiency for future icebreaker and specialized vessel projects.

Seaspan Doubles Pipe Spool Output with the Help of PipeCloud

Seaspan partnered with PipeCloud to modernize pipe spool fabrication, doubling output and going fully digital in support of Canada’s National Shipbuilding Strategy. The collaboration shows how MES technology is transforming marine manufacturing.

Ideal Welders and PipeCloud: Boosting Precision in Pipe Fabrication

Discover how Ideal Welders and PipeCloud enhance precision and efficiency in pipe fabrication processes through advanced technology.

See PipeCloud in Action

Discover how PipeCloud can transform your operations. We’d love to show you how our software helps optimize workflows, reduce manual tasks, and improve decision-making across every stage of a project.

Want to see what PipeCloud can do for your business? Book a personalized demo and explore the future of pipe management. Our team will walk you through key features, share tips, and answer all your questions.

Why PipeCloud