Why PipeCloud

PipeCloud is production software purpose-built for pipe prefabrication.

Why Choose PipeCloud?

Compare PipeCloud side-by-side with other platforms. From performance and scalability to ease of onboarding and use, our comparison table highlights exactly where PipeCloud stands out—so you can make the best choice for your business.

|

Feature

|

PipeCloud

|

SpoolCAD

|

MSuite

|

SpoolFab

|

|---|---|---|---|---|

| Cloud-native | ||||

| Automatic work effort estimates | ||||

| Prefab shop execution | ||||

| Built-in quoting engine | ||||

| Pipe-specific focus | ||||

| Traceability data collection | ||||

| Ease of onboarding |

Digital Pipe Prefabrication

PipeCloud empowers pipe fabricators to take command of their production by eliminating manual processes and unifying everything within a single digital platform.

Key Benefits for Pipe Prefabricators

PipeCloud helps pipe prefabricators foster competitive advantage by automating repetitive tasks, improving visibility, and unlocking more output from the same resources.

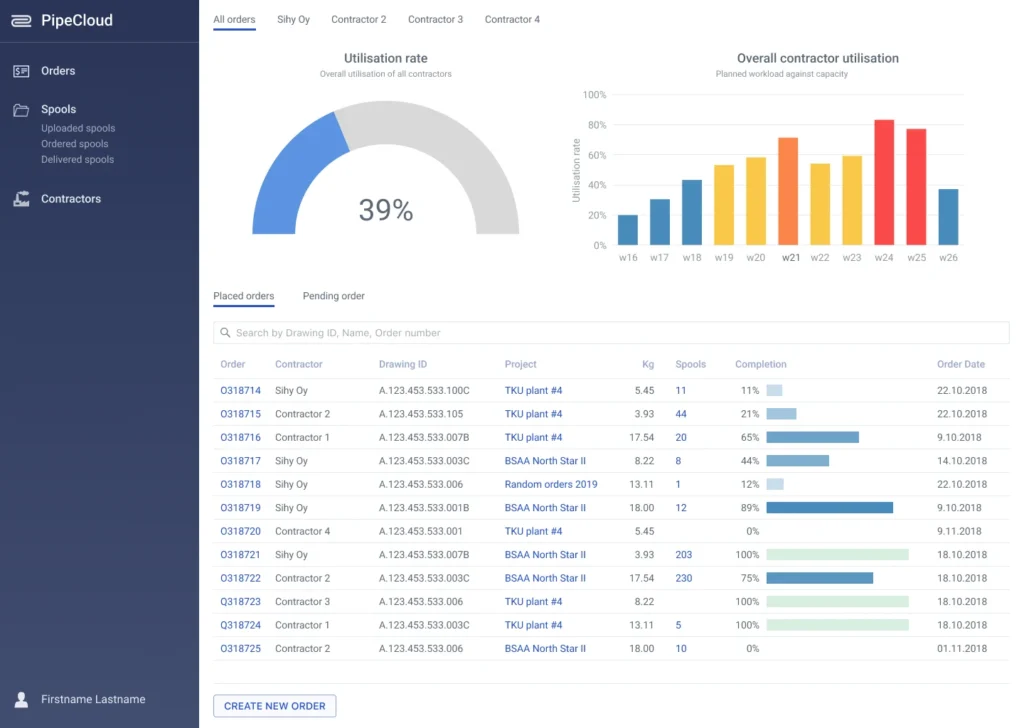

1 Real-time production visibility

2 Less manual work

3 Smarter capacity planning

4 More accurate bidding

5 Higher machine utilization

6 Digital weld traceability

7 Less material waste

8 More consistent shop floor execution

9 Subcontractor management

10 No complex IT setup required

We’ve Got the Tech Side Covered

No complex ERP-style implementation. PipeCloud is delivered as a managed solution—meaning you don’t have to worry about servers, setup, or support. We handle:

- Support – real humans, ready when you need

- Hosting – secure, cloud-based, and up to date

- Implementation – onboarding without disrupting your operations

Implementation

Getting started with PipeCloud is straightforward. Our team learns how your production operates and configures the system to match it. You simply help us understand your layout, processes, and machinery — we take care of the setup, integrations, and go-live support. From there, you can start running production with confidence while we handle continuous updates and support.

Got questions?

We’re here to help.

Your questions matter. Drop us a line anytime. We’ll get back with the details you need.

What Industry Leaders Say About PipeCloud

Hear directly from the pipe fabricators and shipyards using PipeCloud to scale production and improve efficiency.