About Us

Our Story

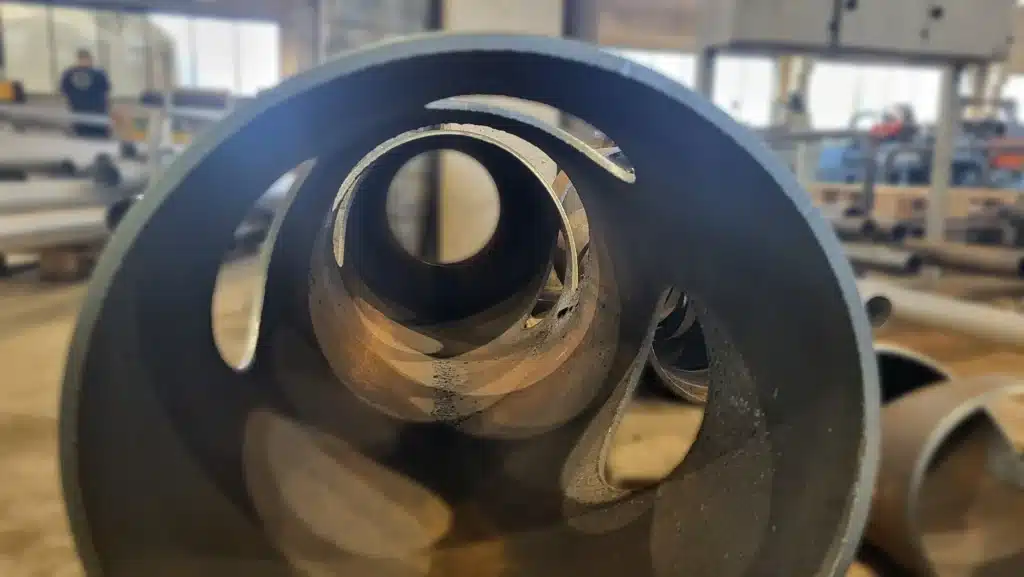

PipeCloud was born inside Finland’s largest marine pipe prefabrication workshop. We faced the same problems many shops do: scattered spreadsheets, late design changes, and coordination that lived in people’s heads. Off-the-shelf MES tools did not fit the realities of one-off spools. So we built something better.

The internal project changed how we worked, enabling to run fully paperless, data-driven production. Productivity improved, material waste dropped, and planners and shop-floor teams finally shared the same live picture of the work. Encouraged by the results, we made PipeCloud available to fabricators and shipbuilders worldwide. Today, PipeCloud is an independent company, fully focused on developing and delivering the best software for pipe prefabrication.

Mission and Vision

Our mission is to make pipe prefabrication smarter, faster, and more accessible. We believe production should be transparent, traceable, and predictable. No guesswork and no reactive firefighting.

Our vision is to be the digital backbone of prefabricated piping so workshops of any size can run modern, efficient, and sustainable operations.

What We Do?

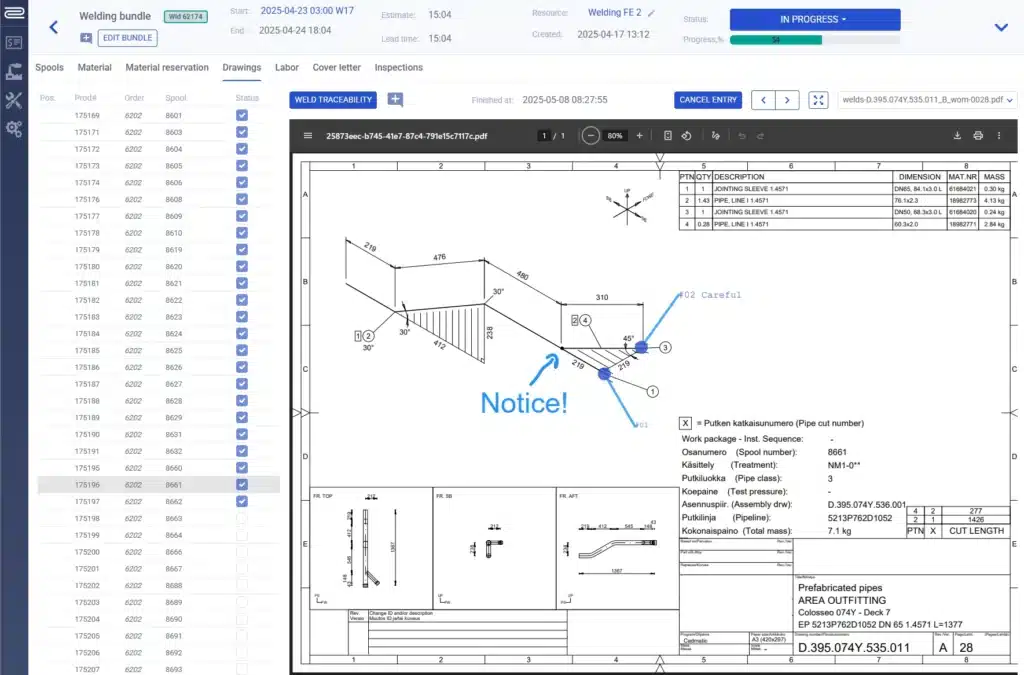

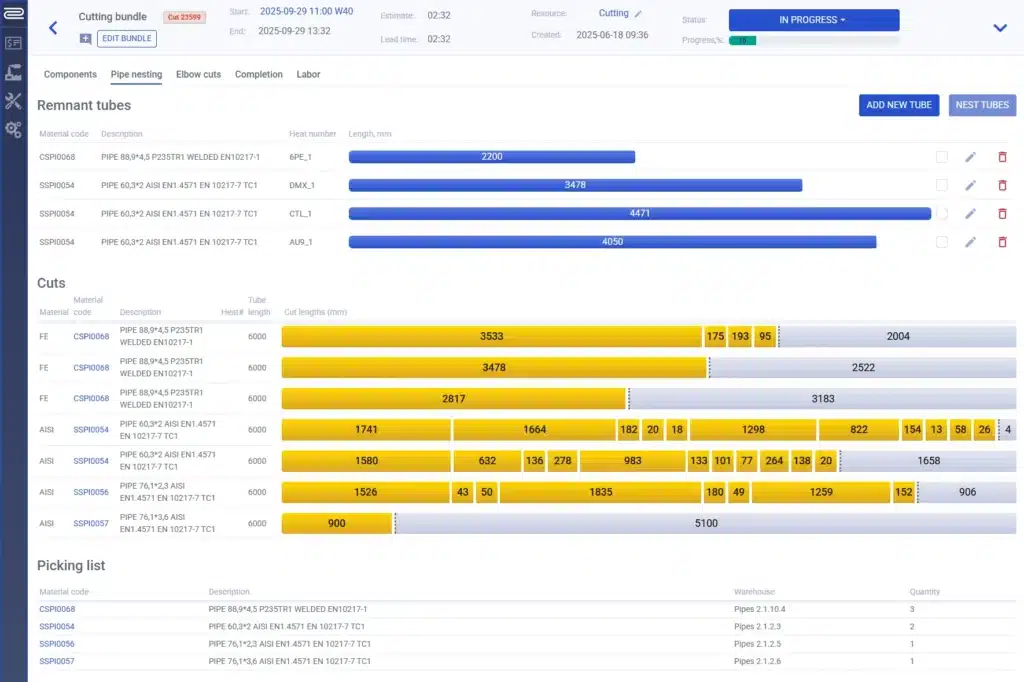

PipeCloud connects the complete, connected workflow from planning to dispatch in one place. It reads spool structures and work phases from CAD files and project documentation, gives real-time visibility across cutting, welding, fitting, and related steps, and records digital traceability for welds, materials, time, and machines. It is fast to learn, so shop-floor users become productive quickly.

Why pipe workshops and shipyards choose PipeCloud?

- Complete workflow in one system, from planning to dispatch

- Automatic extraction of needed data from CAD files and documents

- Real-time status and traceability across production

- 30% higher productivity

- Up to 10% less material waste

- 80% of work planning automated

- more than 300,000 spools produced with the system.

What’s Next?

The future of prefabrication is automated, traceable, and data-connected. We are here to help teams lead that change.

Ready to see how PipeCloud could work in your shop? Book a demo and let’s talk.

Got questions?

We’re here to help.

Your questions matter. Drop us a line anytime. We’ll get back with the details you need.

Contact Us

Jarno Soinila, CEO & Co-founder

Leads PipeCloud’s strategic direction, partnerships, and sales development. Oversees market positioning and works directly with customers to identify opportunities for improving pipe prefabrication efficiency.

Strategy, Partnerships, Sales Development

Olli Yliaho, CTO & Co-founder

Drives the vision and direction of PipeCloud’s technology and product development, ensuring the platform stays ahead of industry needs. Oversees system architecture, feature design, and the long-term evolution of the product.

Technology Vision, Product Development, System Architecture

Vertti Siivola, Technical Solutions Specialist

Heads customer-facing operations, from new client acquisition to successful implementation and ongoing support. Drives customer satisfaction and ensures smooth delivery of solutions.

Sales, Implementations, Customer Success

U.S. Sales Office

Andy Korhonen, Vice President US Operations

Drives PipeCloud’s North American operations, driving business development and customer success across shipyards, industrial fabricators, and mechanical contractors.

US Operations, Business Development, Customer Success