How does digital transformation benefit pipe prefabrication workshops?

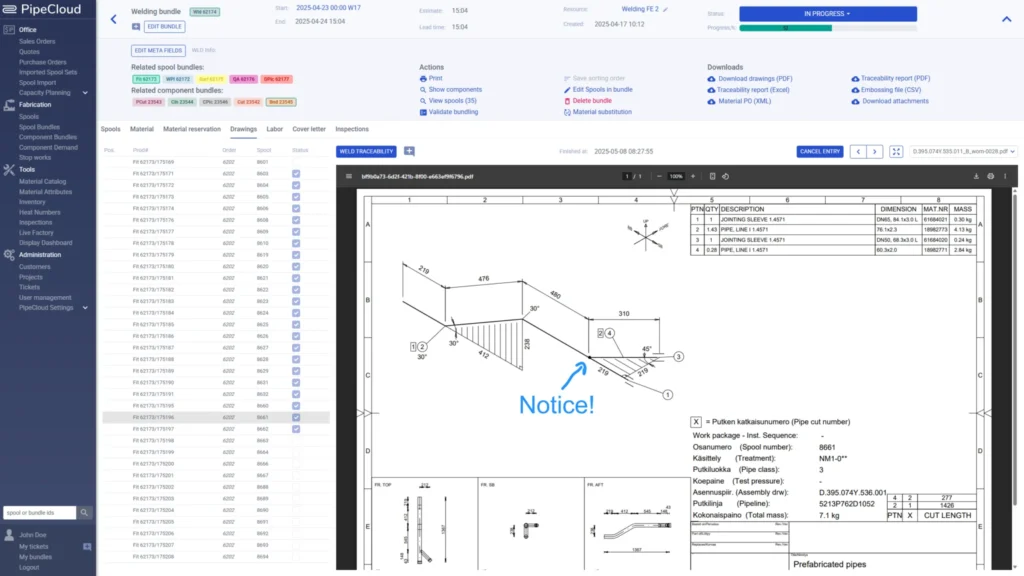

Digital transformation in pipe prefabrication workshops involves shifting from manual processes to data-driven workflows using specialized software. It helps automate critical tasks like CAD data extraction, material planning, work order assignment, and real-time tracking on the shop floor. For pipe fabrication businesses, this means improved efficiency, better traceability, and optimized resource utilization without requiring extensive IT infrastructure. Digital transformation for pipe prefabrication workshops means replacing manual, paper-based processes with automated, data-driven workflows specifically designed for pipe spool fabrication. It’s the integration of purpose-built software that handles the unique challenges of pipe workshops, including managing complex one-off pipe structures, extracting data […]