What is the connection between ERP and MES in pipe fabrication?

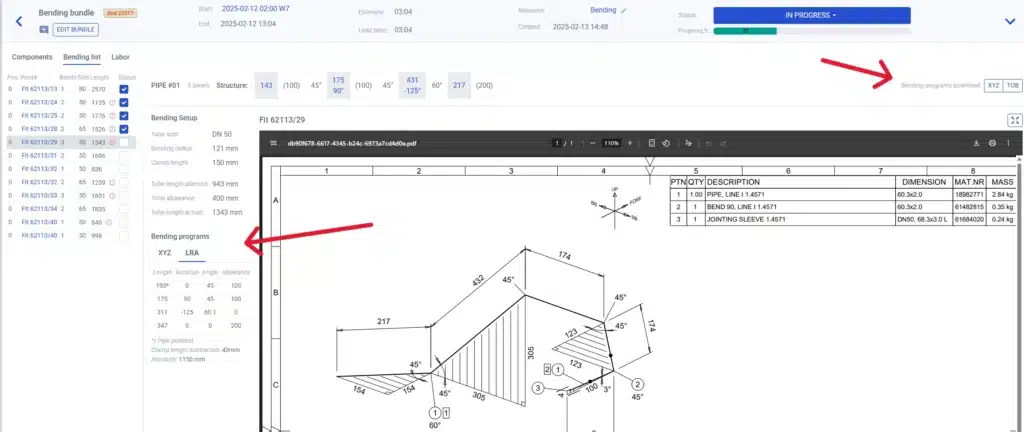

The connection between ERP and MES in pipe fabrication creates a powerful data ecosystem that bridges business management with production execution. Enterprise Resource Planning (ERP) systems handle high-level business processes, while Manufacturing Execution Systems (MES) manage shop floor operations and production activities. Together, they create seamless information flow that eliminates silos, enables real-time decision making, and provides traceability for critical pipe fabrication operations. ERP and MES systems serve fundamentally different purposes in manufacturing. ERP systems manage business-wide processes like accounting, procurement, and order management, while MES systems control production-specific activities like scheduling, work instructions, and shop floor data collection. ERP […]