Automatic bending programs — reduce manual work and errors, streamline production

PipeCloud automates bending program generation based on the exact geometry of each spool and the configuration of the bending machinery used in your pipe workshop. Instead of relying on manual calculations or hand-transferred data, pipe benders receive a ready-to-use program tailored for each job. This eliminates unnecessary steps, reduces errors, and lets operators focus on their core task: executing precise bends.

The challenge: Manual bending setup is slow, error-prone, and reliant on specialists

In many workshops, creating accurate bending programs still requires significant time and expertise. Operators or engineers must calculate the correct parameters by hand or with disconnected tools, and transfer that data to the machines — often by USB sticks or handwritten notes. Every step in this process introduces room for error, delays, or rework, especially when production schedules are tight.

Even small mistakes in bending can result in scrapped material or unusable spools — wasting time, money, and effort.

From spool geometry to bending program, all in one system

PipeCloud automates bending program creation by reading spool geometry directly and generating the required parameters based on the specific bending machine defined in your setup.

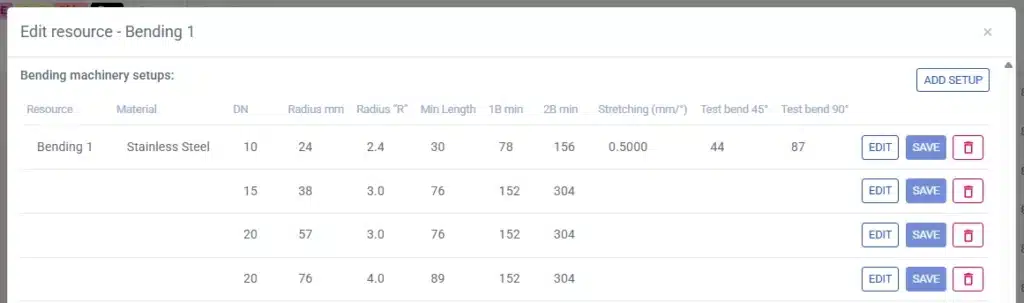

In the resources section of PipeCloud, each bending machine used in production can be configured. For every bending resource, machine-specific parameters can be input and saved. These form the basis for generating accurate bending programs tailored to both the spool and the machinery used.

When the production planner allocates a spool that includes bends to a specific bending resource, PipeCloud automatically generates the correct bending program based on that machine’s configuration.

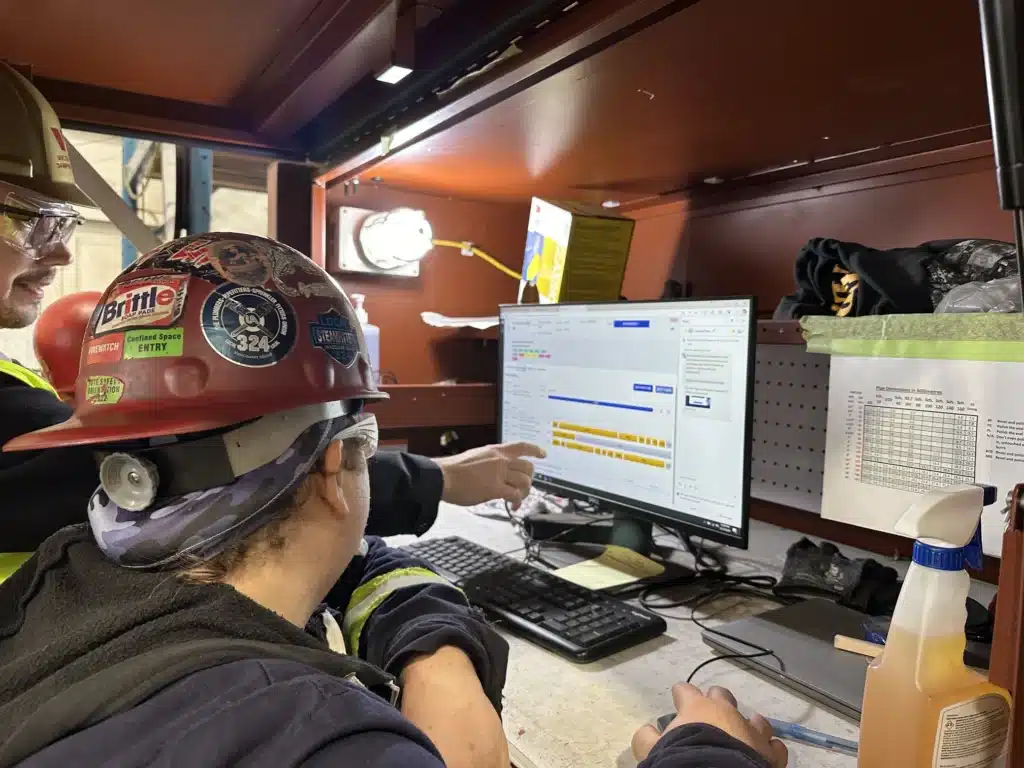

This information is presented as part of the work order that the shop-floor worker accesses on the workstation’s touch screen — clear, ready, and without additional steps.

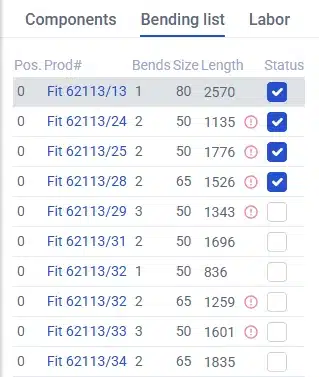

PipeCloud supports both TOB (Table of Bends) and XYZ format bending programs, ensuring compatibility with a wide range of machinery setups and workflows. Operators can download the needed bending program directly from the bending work order.

Clear tasks, reduced errors

On the shop floor, the bending operator simply opens the work order in PipeCloud — where the correct bending program is instantly visible and available for download. They can begin work immediately without needing to recheck parameters or search for setup details.

Once a spool is bent, the operator marks it as complete in PipeCloud and moves on to the next task. The system provides access to the correct machinery setup and bending program for each spool, supporting a smooth, uninterrupted workflow.

Because bending resources are defined just like other shop-floor stations, planners can allocate work clearly and avoid bottlenecks or idle time. Each completed bend is reflected in the overall progress of the bending production bundle for a set of spools, providing real-time visibility and traceability across the shop.

What it means in practice

Instead of spending time calculating bend angles or checking machinery settings, the bender receives a digital work order that includes everything they need. If a pipe requires bending on Machine A, PipeCloud automatically provides the correct program for that machine — visible on the shop-floor screen and ready to download.

There’s no need to convert files, check compatibility, or involve supervisors — the task is ready to go. This saves time, reduces errors, and shortens lead times. With fewer steps and clearer tasks, the operator can focus on precision execution — not chasing down data.

Better planning. Fewer errors. Faster execution.

Automated bending calculations in PipeCloud help you:

- Eliminate manual setup and data entry

- Ensure accurate bending results for each spool

- Free up skilled personnel from repetitive tasks

- Shorten production lead times

- Reduce material waste and rework

- Integrate bending seamlessly into your end-to-end prefabrication process.

Ready to see it in action?

Book a demo and explore how PipeCloud simplifies bending program generation and improves your production flow from planning to execution.

Explore PipeCloud and browse more features!