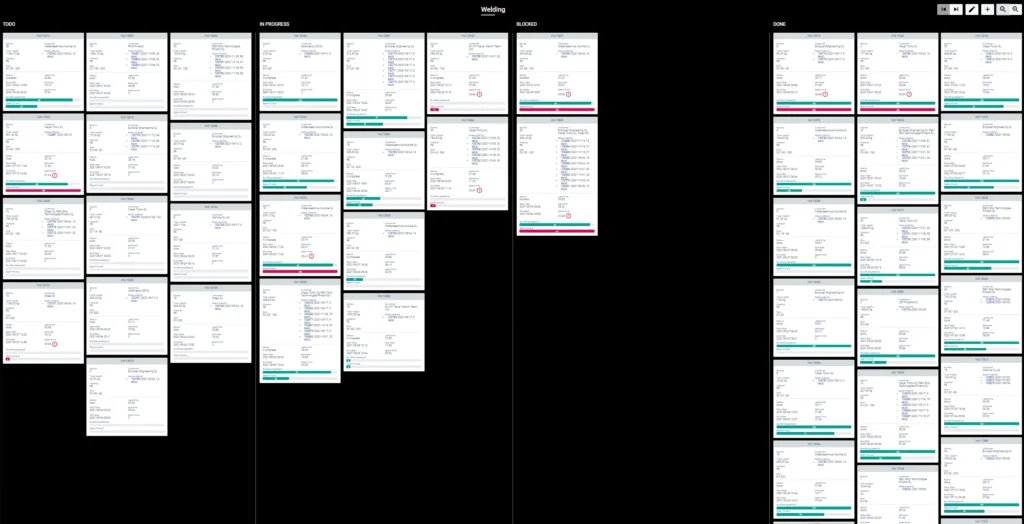

Kanban view in PipeCloud — get a live overview of production tasks at a glance

PipeCloud’s Kanban view provides a real-time visual overview of all active production tasks. It shows what’s in progress, what’s waiting, and what’s blocked. Supervisors and planners get the clarity they need to manage shop floor activity without relying on spreadsheets, walkarounds, or guesswork.

The challenge: No central visibility into work status

In traditional pipe prefabrication environments, it’s difficult to assess the current status of the shop floor without physically checking each station. Progress, capacity, and delays are often tracked manually or not at all. The lack of visibility creates bottlenecks, missed handoffs, and reactive decisions.

Without a central view, it’s hard to know:

- What’s actively being worked on

- Whether certain teams are overloaded or idle

- If upcoming deadlines are at risk

- How actual time compares to the estimate

Visual clarity for every task

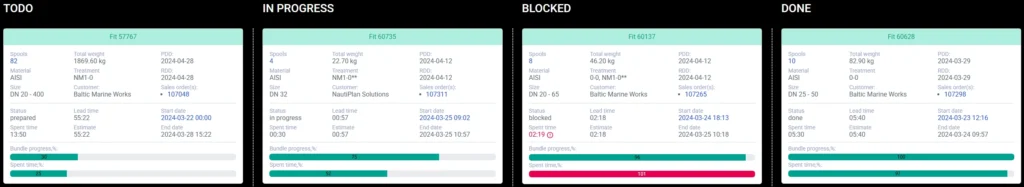

PipeCloud’s Kanban view organizes pipe prefabrication production bundles — such as cutting, bending, welding, or fitting — into four real-time states: To-do, In progress, Blocked, and Done.

Each bundle is displayed as a card that includes:

- Number of spools

- Customer and order reference

- Start and end dates

- Planned vs. actual time spent

- Progress and time usage as percentages

Color coding by task type (e.g. fitting in green, cutting in light red) makes it easy to scan and identify status at a glance. Because the view updates in real time, supervisors can monitor activity from a screen on the wall, a laptop, or a mobile device without losing track.

Customize your view to focus on what matters

The Kanban view can be configured to show only the bundles that are relevant to your workflow. You can select specific production resources, choose how long completed bundles remain visible, adjust the refresh interval, and decide whether to use the view on a tablet, mobile device, laptop, or kiosk display. These settings can be saved as dashboard profiles, allowing teams to quickly switch between views tailored for different roles, stations, or project scopes. Whether you’re managing fitting and welding or monitoring all current activity on the shop floor, the Kanban view can be adjusted to support your priorities.

From insight to action

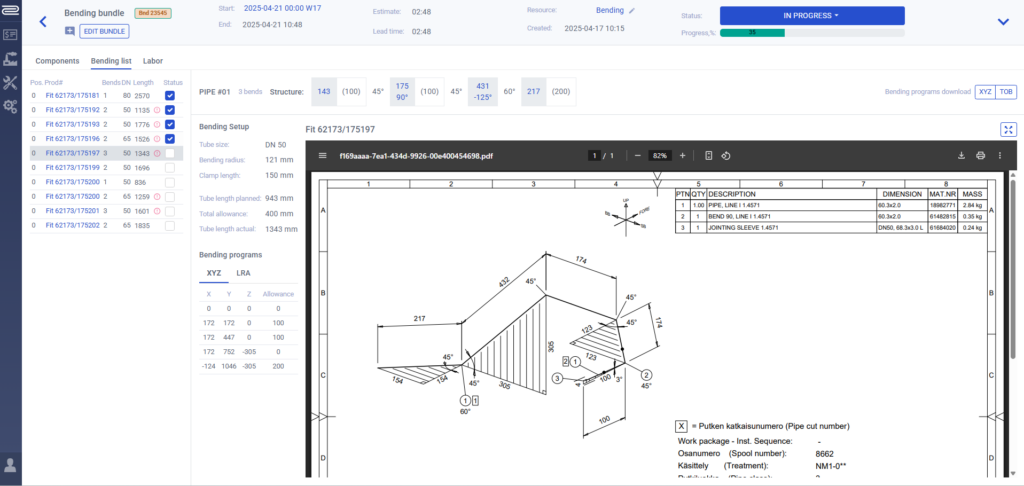

When a bundle needs attention, simply click it to open the detail view. Supervisors can immediately check how far the task has progressed, whether the team has exceeded the time estimate, and what might be holding things up. This helps in making timely decisions, whether it’s reallocating resources, resolving a material shortage, or flagging a bigger scheduling issue.

The Kanban view makes it easy to:

- Compare actual vs. estimated time

- Identify early signs of delays or inefficiencies

- Take corrective action quickly, both in real life and in PipeCloud

If few bundles are moving, it may reveal underutilized resources or a gap in task handoffs. If some tasks are well over time, it may point to recurring issues that need to be addressed. This real-time awareness lets supervisors and planners act before problems cascade.

Why it makes a difference

Without a digital Kanban, it’s easy for delays to go unnoticed until they cause bigger problems. Shop floor status becomes a matter of gut feeling or back-and-forth communication. PipeCloud changes that by making live production data visible, structured, and immediately useful.

Planners can also use the Kanban view to:

- Check if a new urgent order can fit into the current load

- Estimate upcoming bottlenecks based on live task volumes

- Monitor whether key deliveries are on track or at risk

Production clarity, without the overhead

PipeCloud Kanban gives your team a real-time window into production. No spreadsheets, no walking the floor, no waiting for updates. Just live, actionable insight into what’s happening and what needs attention — whether you’re managing a single team or coordinating across projects.

Ready to see it in action?

Book a demo and explore how PipeCloud Kanban view helps you stay ahead of production issues, manage tasks visually, and improve shop floor coordination in real time.