Parsing PDF spool drawings in PipeCloud — eliminate manual entry from the start

PipeCloud’s automatic spool drawing parser lets you upload PDF spool drawings and instantly extract critical data like spool ID, pipeline, revision number, materials, and more. This removes the need for production planners to manually read and transcribe data — saving hours of work and eliminating errors at the very first step of the production process.

The challenge: Manual parsing slows everything down

In traditional pipe prefabrication workflows, new customer orders often arrive with hundreds of spool drawings. Each customer might use a slightly different format, making automation difficult. Planners are forced to open each drawing, locate the required data manually, and retype it into spreadsheets or internal systems. It’s time-consuming, error-prone, and adds no value to the process.

As spool volume grows, this bottleneck only gets worse. Planners spend more time managing information than optimizing production.

From drawing to data — automatically

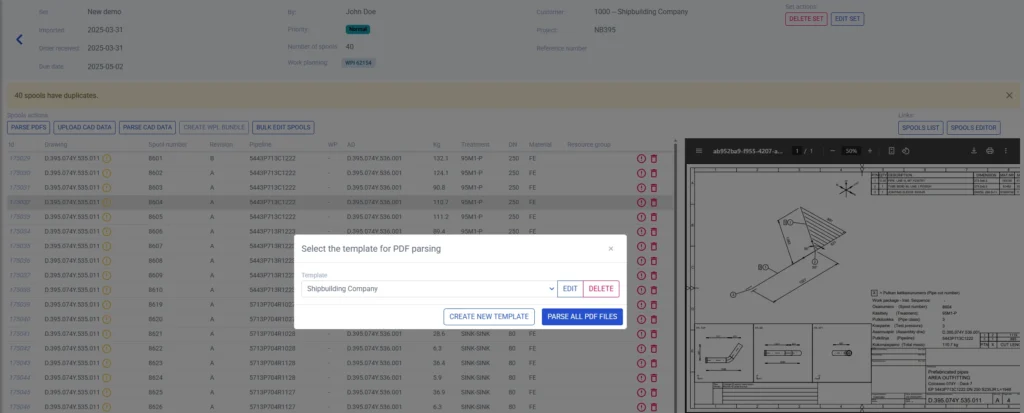

With PipeCloud, you can upload a batch of spool PDFs and extract all relevant spool information in minutes. The system reads each drawing using a customer-specific parsing template and creates a clean, structured list of spool data ready for production use.

What PipeCloud extracts from PDF files:

- Spool number

- Drawing name

- Revision number

- Pipeline

- Work package

- Assembly drawing number

- Treatment materials

- Pipe class

- Test pressure

- Work package

- Price class

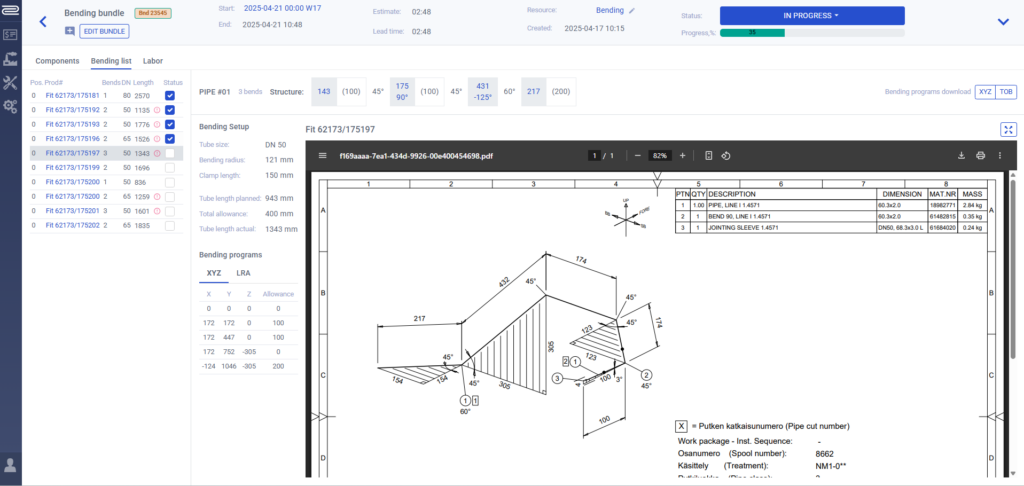

Parsed data flows directly into PipeCloud’s planning tools, where it can be used to generate work orders, allocate resources, calculate workload, and track progress across stations. Everything is linked, searchable, and fully traceable — no more scattered files or disconnected spreadsheets.

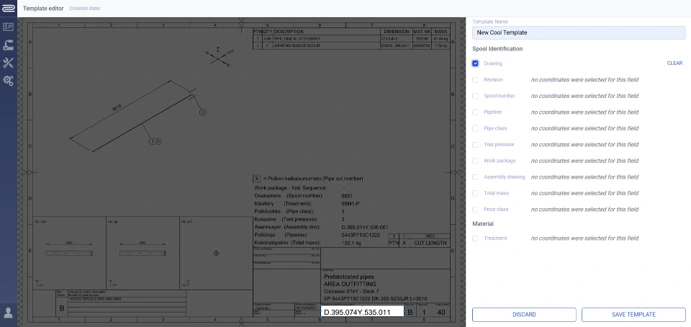

Parsing templates: Fast setup, reusable for every customer

Because customer drawings differ in layout and content, PipeCloud allows you to create parsing templates tailored to each customer’s document format. The template creation process is fast and visual:

- Simply drag fields over the drawing to define where each data point is located

- Assign labels like “spool number” or “pipe class”

- Save the template and reuse it for all future orders from that customer

Templates can be created in minutes and ensure reliable, repeatable data parsing with every new drawing batch. You can maintain a library of parsing templates for each customer or drawing template, and select them easily when new spool orders come in.

How it helps in practice

Say you receive a 300-spool order from a returning customer. Instead of reading and retyping each drawing by hand, the planner uploads the PDFs, selects that customer’s parsing template, and clicks parse. Within minutes, all key spool data is available and connected to planning tools. That same data can be used to create work orders, manage capacity, and plan downstream tasks — saving hours of manual work.

Built for real production environments

This feature is essential for pipe prefab shops of any size. Whether you’re producing standard spools or handling complex modules with dozens of variations, PipeCloud handles inconsistent drawing formats with ease. For operations juggling multiple customer projects or high spool volumes, it dramatically reduces the administrative burden on planning teams.

Results that matter

By automating PDF drawing import and parsing, PipeCloud helps reduce production planning workload by over 80%. It improves data accuracy, accelerates onboarding of new orders, and provides a structured foundation for the entire production process. That means fewer delays, fewer errors, and more time for planners to focus on improving efficiency, not just surviving the workday.

Ready to see it in action?

Book a demo and explore how PipeCloud simplifies spool data handling, speeds up planning, and sets your production up for success — right from the drawing.