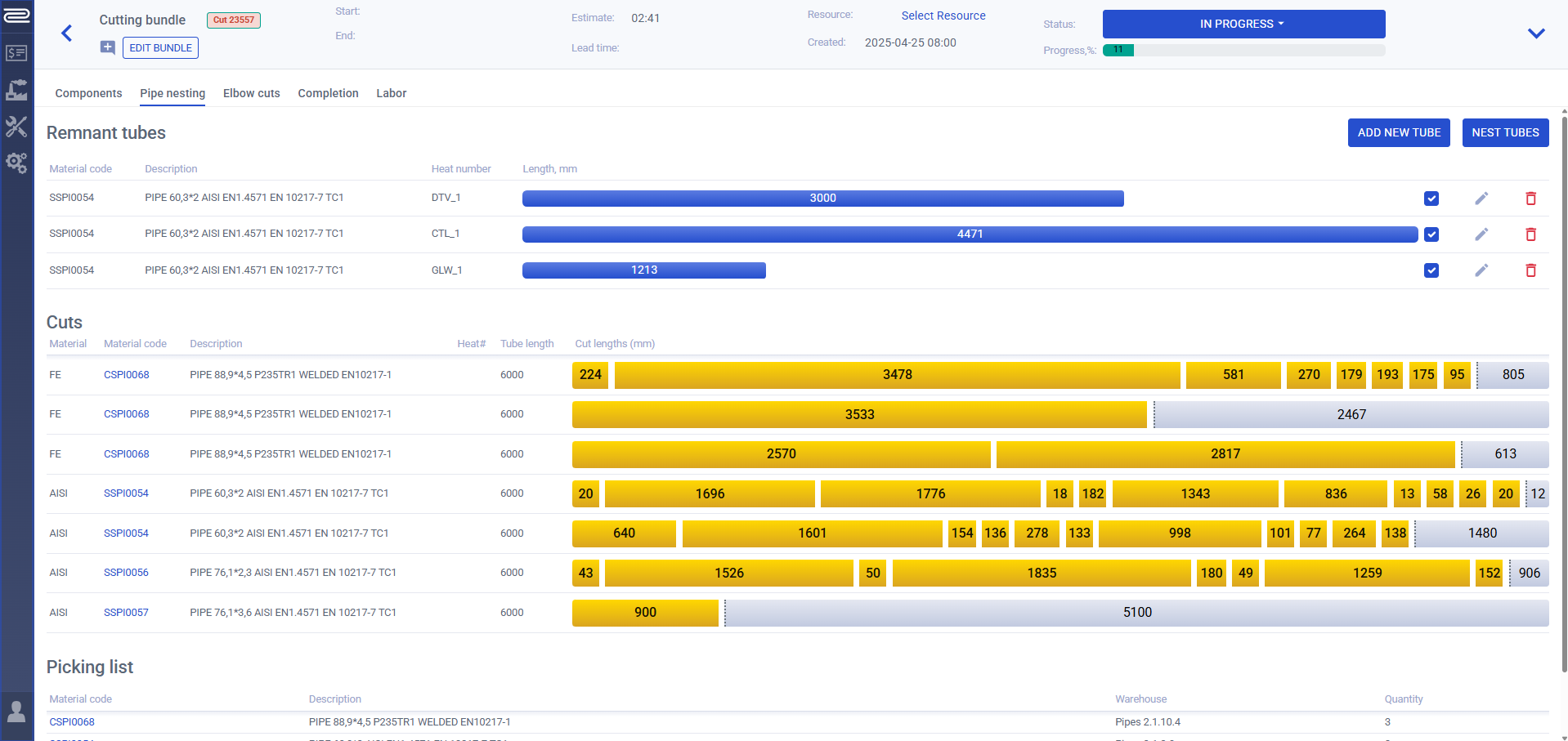

Cutting is typically the first phase in pipe prefabrication. PipeCloud automatically generates a cutting work order for each spool that requires it. This work order includes all the information the saw operator needs — from which raw tubes to pick from the warehouse to optimal nesting, cut lengths, and pipe marking instructions.

PipeCloud makes it easy to collect heat numbers or use existing heat numbers within the same workflow. It also supports the use of leftover materials from previous cutting jobs. These leftovers can be selected directly, and the nesting is automatically recalculated to make the most efficient use of material.

The UI screenshot below shows an example of a typical work order in PipeCloud.