PipeCloud Exhibiting at FABTECH Chicago 2025

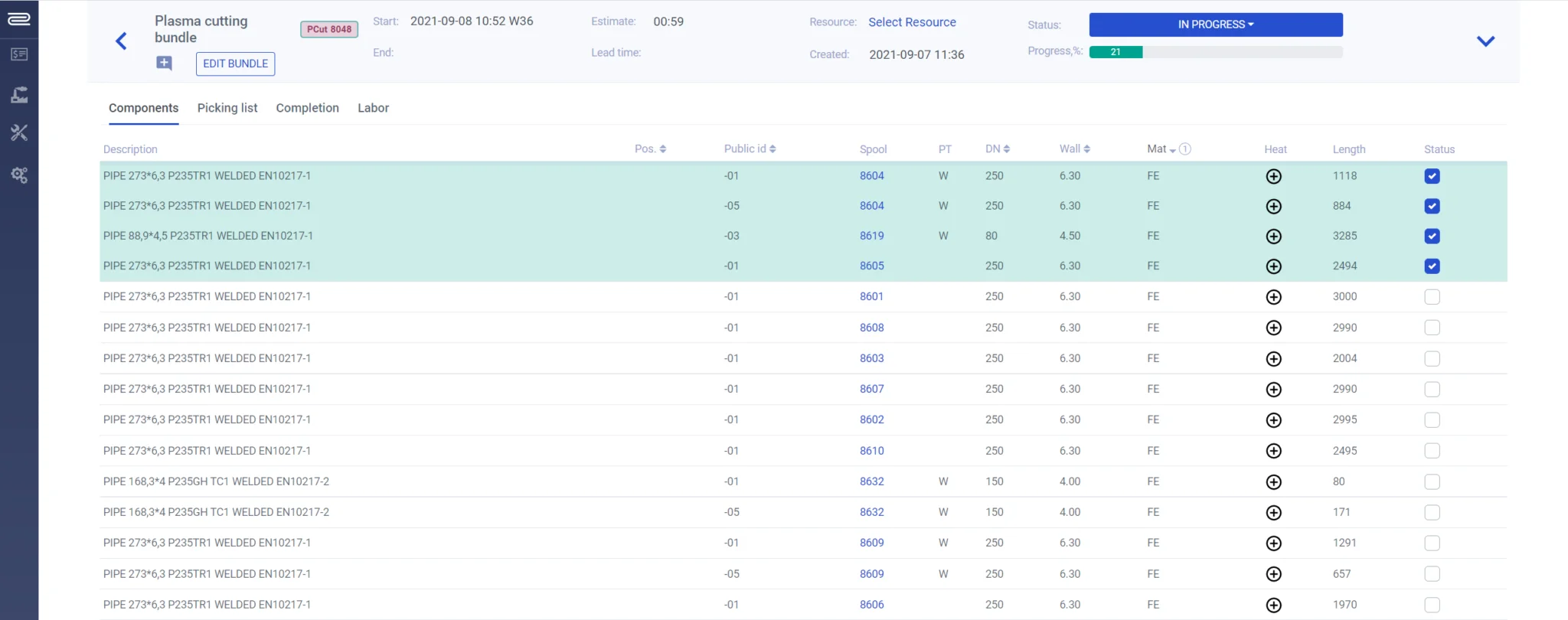

PipeCloud is exhibiting at FABTECH 2025 in Chicago! Visit us at Booth D42542 to see how our SaaS platform brings smart, digital tools to pipe prefabrication. Experience live demos and explore how we solve real challenges in planning, tracking, and production management.