Welding quality is critical in pipe prefabrication. If 10% of welds fail X-ray spot checks at the installation site, the customer may demand 100% inspection — leading to costly repairs, delays, and rework.

PipeCloud helps avoid this by offering built-in tools for quality assurance. You can:

- Create inspection work orders

- Record welder-performed checks using custom meta fields

- Use WeldEye integration for WPS management and documentation

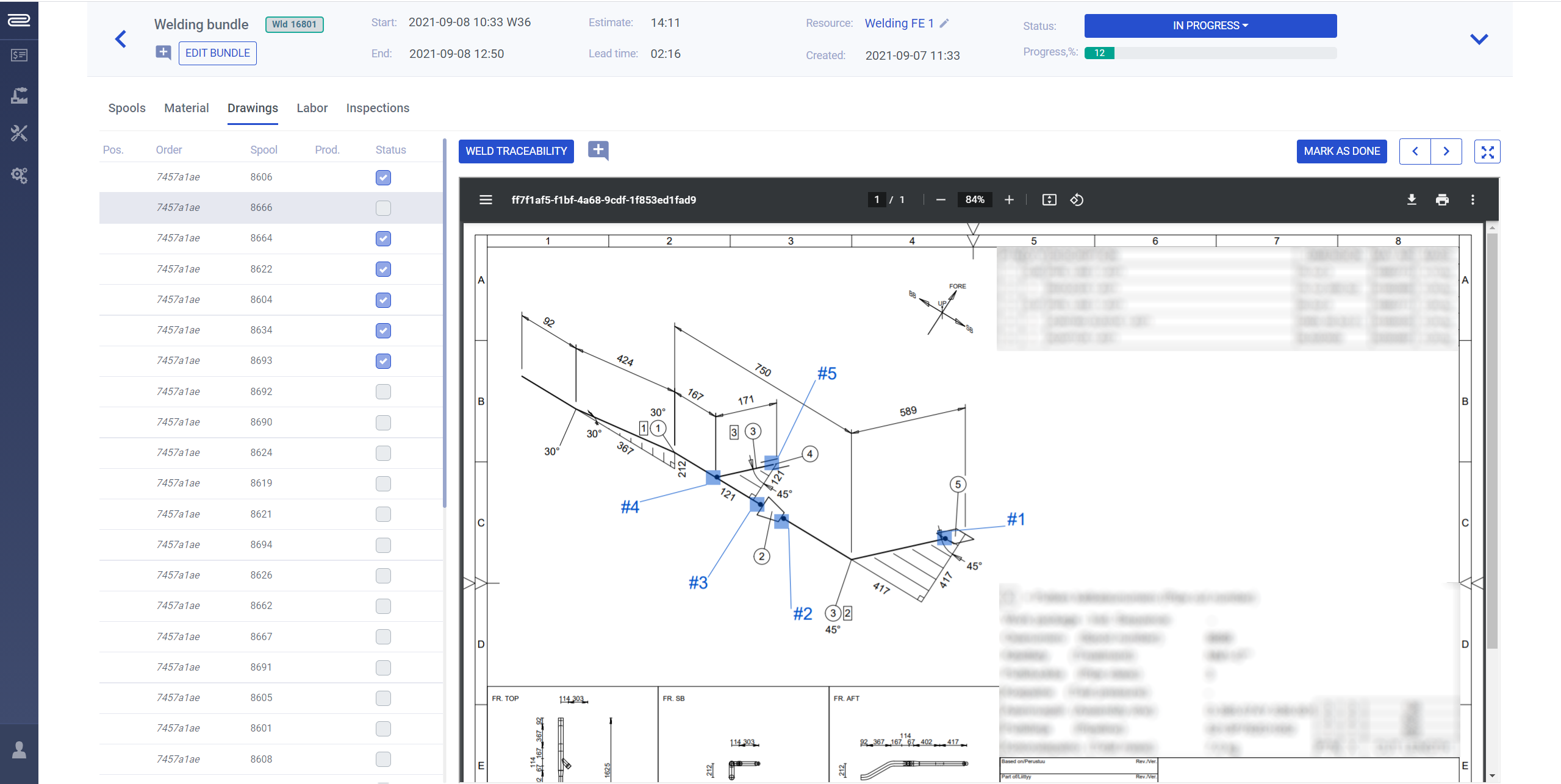

After the fitter completes spot welding, the welder can begin. In the welding bundle view, PipeCloud shows:

- Required weld types

- Traceability and QA inspection requirements

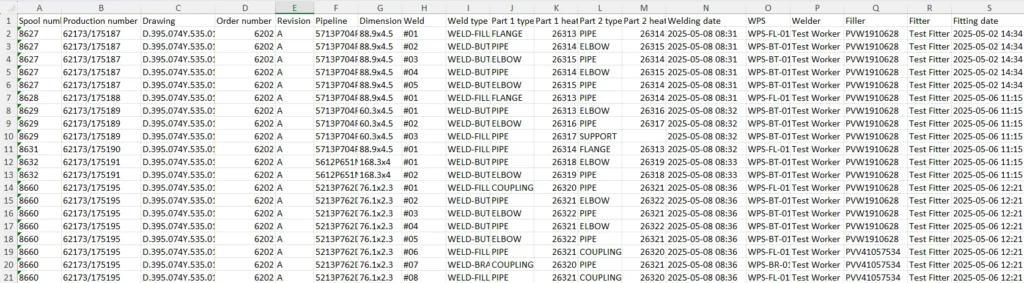

Welding traceability data can be entered directly in the PipeCloud welding bundle view. All traceability data entered in PipeCloud can be retrieved at any time — whether for QA audits, customer reporting, or resolving issues discovered after installation. Read more about PipeCloud’s welding traceability feature here.

Alternatively, the welder can use WeldEye by Kemppi for WPS management and traceability collection. PipeCloud has integration with WeldEye, enabling you to send welding work orders directly and synchronize documentation between systems.