PipeCloud was recently featured in Douglas Magazine as part of an in-depth article covering Seaspan’s new pipe-spool prefabrication facility at Ark Road near Shawnigan Lake, British Columbia. You can read the full original article here.

The article, “No Pipe Dream: Seaspan Utilizes Intelligent Software to Drive Efficiency at New South Island Manufacturing Facility” (published November 17, 2025), highlights how Seaspan is modernizing pipe prefabrication by combining robotics, centralized production, and digital workflows to support major shipbuilding programs, including Canada’s National Shipbuilding Strategy.

Digital pipe prefabrication at scale

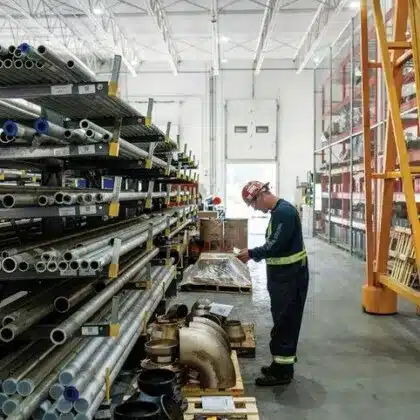

According to the article, Seaspan’s Ark Road facility brings pipe prefabrication into a single, purpose-built location, allowing better control over production, improved agility, and a more streamlined workflow.

“Investing in this facility really has given us good control of what our production is, to support the vessels that we’re building in [North] Vancouver and allows us to be a lot more agile,” says Neil Fraser, program manager at the three-month-old, 40,000-square-foot Ark Road facility. “When you combine all of it into one location, it does streamline the workflow quite a bit. There’s a lot of positives to having it all, like in a one-stop shop so you’re not shipping parts all over town to different suppliers, different manufacturers doing different things. There’s a good upside to consolidating and having all your processes in one location.”

As part of this setup, Seaspan has integrated PipeCloud into its pre-production process. The article describes how PipeCloud enables a fully digital workflow that replaces traditional paper-based planning and documentation.

“It’s a full-digital workflow: there’s no more paper, you’re not releasing printed drawings and having to collect drawings back when you have revisions,” Fraser says of the intelligent software. “You can shut them off online and you can put new drawings into the package, the data collection is all digital, so you’re not losing bits of paper. Everything is linked, via PipeCloud.”

Where prefabricating pipe has traditionally involved manual planning, paper documents, and separate tools, PipeCloud’s digitalization of the process creates a connected system that automates planning, coordinates work, and tracks progress through every production stage until completion.

From evaluation to live production

PipeCloud first engaged with Seaspan roughly two years ago, after which a Seaspan team visited Finland to see the software in active production use. “At the end of February we went live with it in Victoria at the shipyard itself, and later moved up here [to Shawnigan Lake] and became live with every work centre set up with touch-screen control,” Fraser says.

Supporting efficiency and workforce longevity

The article also highlights how Seaspan has paired digital workflows with robotics, including spool-welding robots, to improve efficiency while supporting the workforce.

“We’ve implemented two spool-welding robots, which is a real benefit to the workforce,” Fraser says. “We have managed to extend the workers’ careers — some of them would age out of being able to do some of this type of work, and it allows us to keep people who otherwise would move on to other things, working within the industry. It’s a real plus.”

Independent recognition

We are proud to see PipeCloud referenced in independent industry coverage alongside Seaspan’s investment in modern, connected pipe prefabrication. The Douglas Magazine article reflects a shared focus on practical digitalization, production visibility, and scalable manufacturing for complex shipbuilding environments.

Read the full article on Douglas Magazine:

https://www.douglasmagazine.com/seaspan-victoria-pipecloud-robotics

Got questions?

We’re here to help.

Your questions matter. Drop us a line anytime. We’ll get back with the details you need.