Capacity planning

PipeCloud’s capacity planning helps you balance shop floor resources, assign tasks with precision, and plan production efficiently. Gain real-time visibility to avoid bottlenecks and keep schedules on track.

PipeCloud streamlines production planning with automatic CNC programming, optimized pipe nesting, and built-in capacity planning tools.

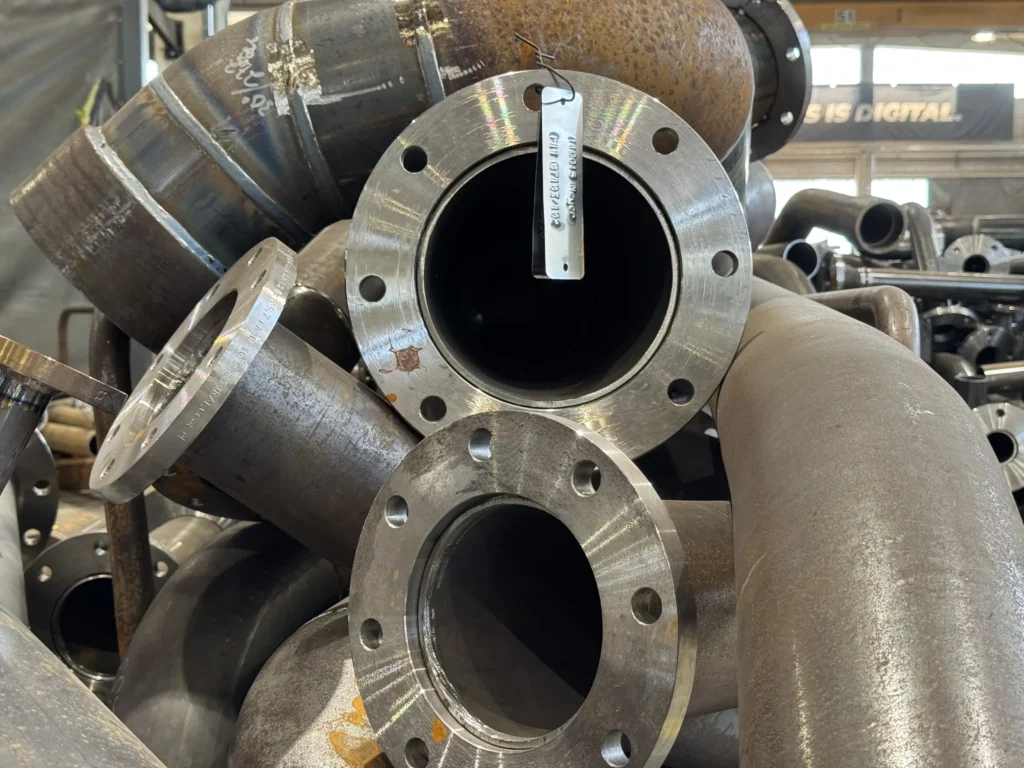

In many cases, the originally designed pipe spool or pipeline cannot be manufactured exactly as planned. Large pipelines often need to be split into smaller, more manageable spools. Some pipes may require additional welds. Bends might need to be replaced with elbows, or vice versa. Managing these changes — along with generating CNC programs, calculating cutting lists, nesting pipes efficiently, and creating optimized work orders — is time-consuming and complex.

Planners must also estimate labor across all work phases, balance workloads between stations, and align production with available capacity to maintain high Overall Equipment Effectiveness (OEE). Without the right tools, this level of coordination is difficult to maintain.

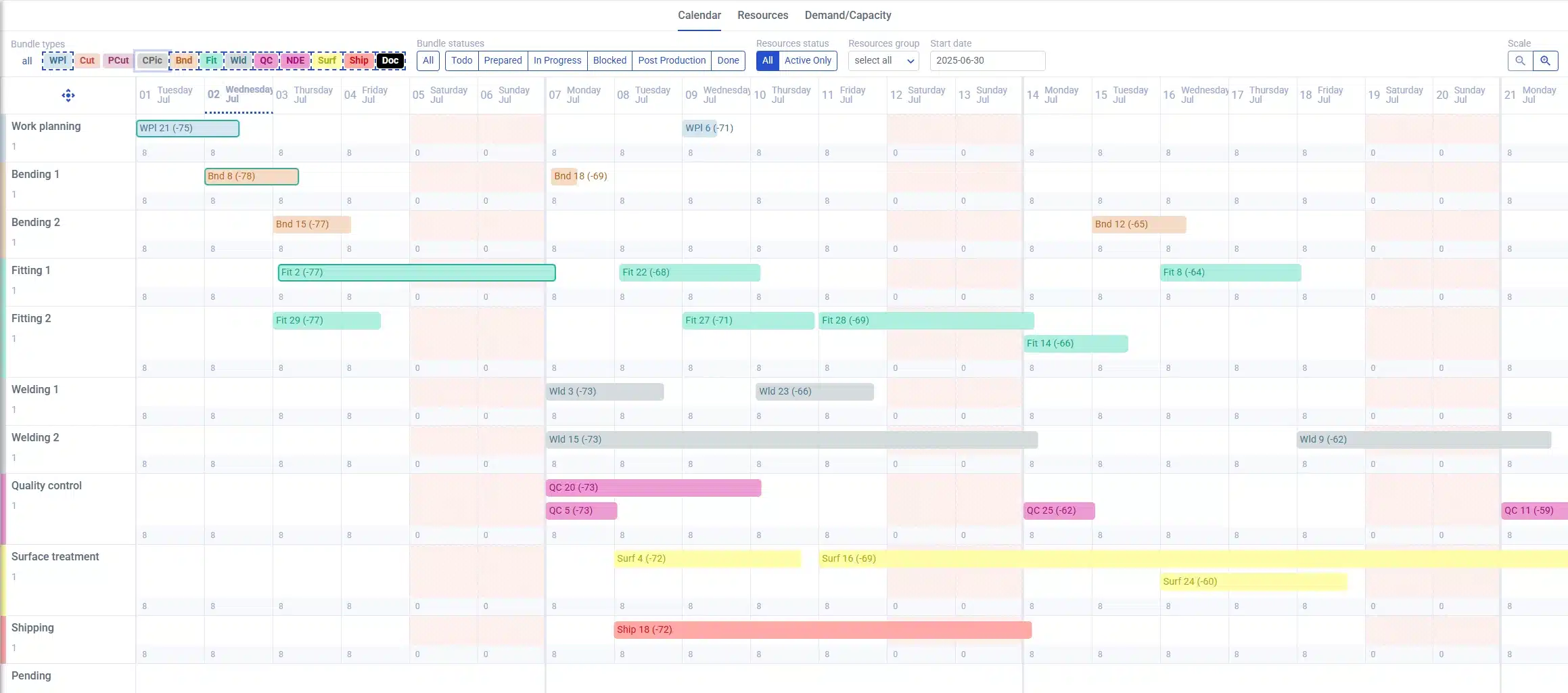

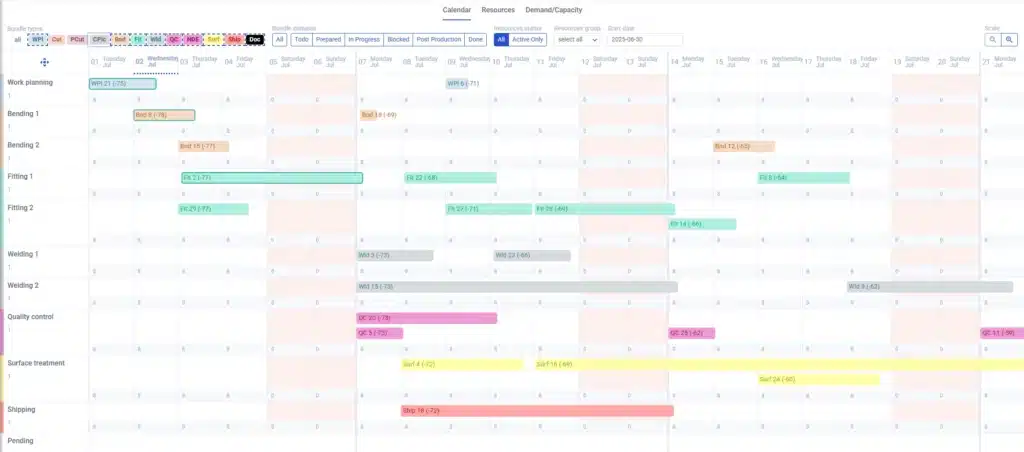

PipeCloud streamlines this entire planning process by intelligently extracting critical data directly from design files. This includes advanced features like PDF Parsing and PCF Parsing that automatically interpret spool drawings and piping component data. Interactive views support planners in organizing, sequencing, and adjusting the workflow from cutting to dispatch. Tools like the Capacity Planning view help maintain balance across the full production schedule.

PipeCloud capacity calendar shows work tasks allocated to different resources in a calendar view.

Your questions matter. Drop us a line anytime. We’ll get back with the details you need.

PipeCloud’s capacity planning helps you balance shop floor resources, assign tasks with precision, and plan production efficiently. Gain real-time visibility to avoid bottlenecks and keep schedules on track.

Learn what a material heat number is, its role in pipe fabrication, and how it ensures material traceability, compliance, and integrity with modern tools.

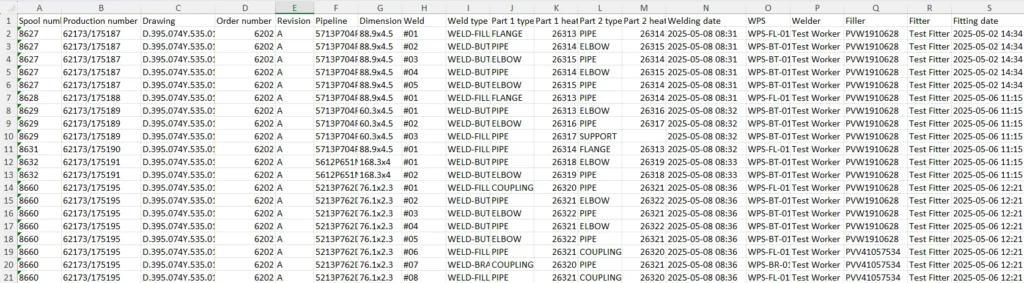

Welding traceability made easy. PipeCloud’s feature lets you log, trace, and report welds instantly. Reduce rework, ensure compliance, and catch issues early.

Find the best industrial piping cost estimator with our guide. Learn how to choose tools that ensure accurate quotes, efficiency, and project success.

Discover what pipe spools are, their components, and how they’re fabricated. From design to inspection, learn the key steps in creating quality pipe spools.

Learn the complete pipe fabrication workflow, from design to assembly. Look into processes, components, best practices, and modern innovations in fabrication.

“You can easily see that all the preconditions are ready for fitting. PipeCloud shows you the status of all the previous work phases, so you don’t have to run around the factory with papers”

Digitalization of welding accelerates when the capability of the most intelligent welding machines is combined with the information produced by a unique manufacturing execution system …