PipeCloud Selected by Helsinki Shipyard to Drive Digital Transformation in Pipe Prefabrication

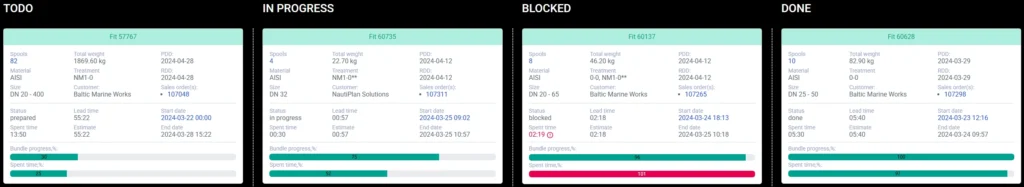

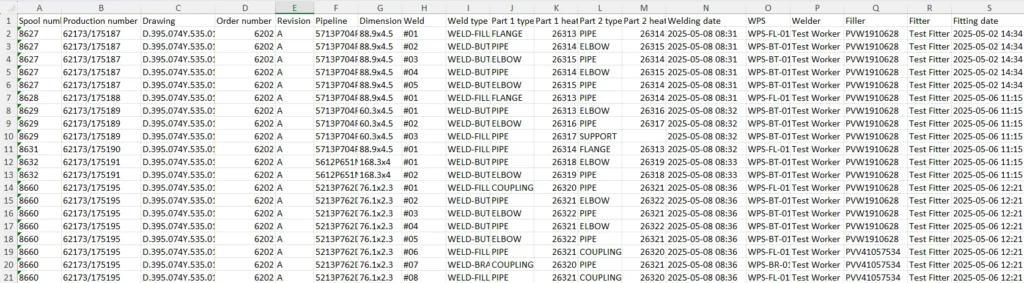

PipeCloud has been selected by Helsinki Shipyard to modernize pipe prefabrication with a digital platform. The partnership strengthens Helsinki’s shipbuilding capabilities as production scales under Davie ownership, combining heritage expertise with real-time visibility, advanced planning, and improved efficiency for future icebreaker and specialized vessel projects.