Welding traceability in PipeCloud — track every weld with precision before issues escalate.

PipeCloud’s welding traceability tools give you full visibility into weld data that can be retrieved and reviewed anywhere, anytime. This helps you meet industry requirements, prevent costly rework, and avoid catastrophic failures when issues surface only after the pipes are already installed and in use.

Why traceability matters

Weld quality is a critical factor in pipe prefabrication. If even a small percentage of welds fail inspection, especially during site installation, it can trigger full project audits, expensive rework, and serious delays. In regulated industries like naval shipbuilding, LNG, offshore, and nuclear, welding traceability isn’t just a best practice; it’s a requirement.

Without a digital system, identifying the root cause of a weld defect is slow and unreliable. Paper records and disconnected QA workflows make it difficult to trace problems back to a specific welder, filler batch, or material heat number — and nearly impossible to know where else the same risk may exist.

Everything tracked, in one place

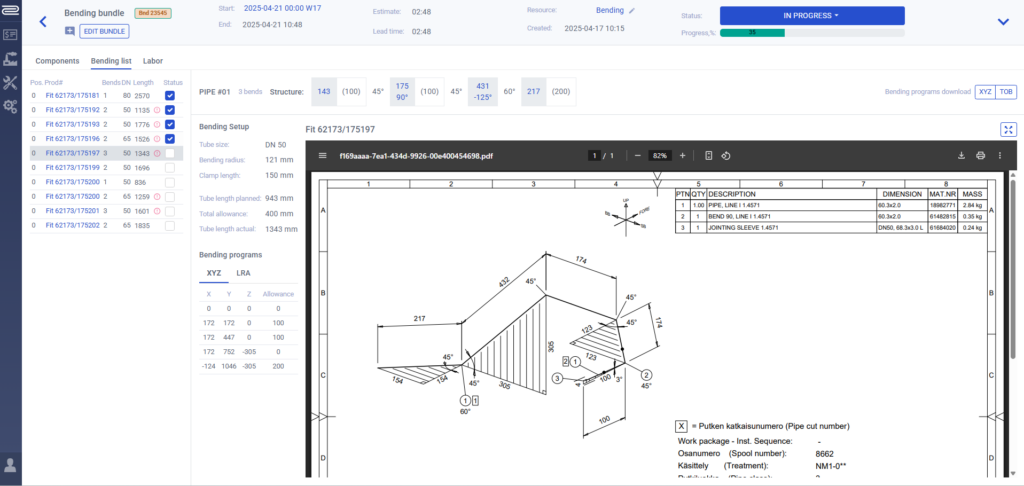

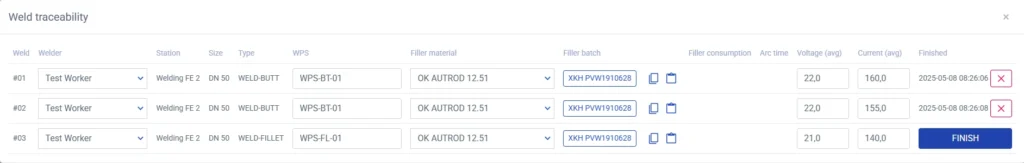

PipeCloud provides your welders with a straightforward interface to record critical weld data during production. Key details tracked include:

- Welder name

- Weld type

- Pipe size and station

- WPS used

- Filler material and batch

- Filler consumption

- Arc time, voltage, and current

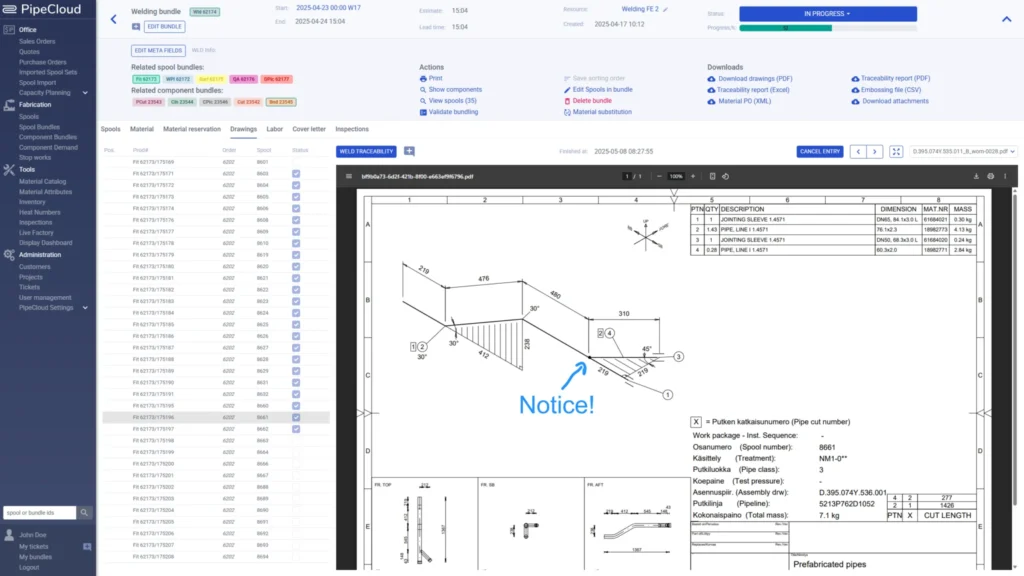

All data can be reviewed, filtered, and exported when needed. If problems are found during or after production, similar welds can be identified and flagged for inspection quickly.

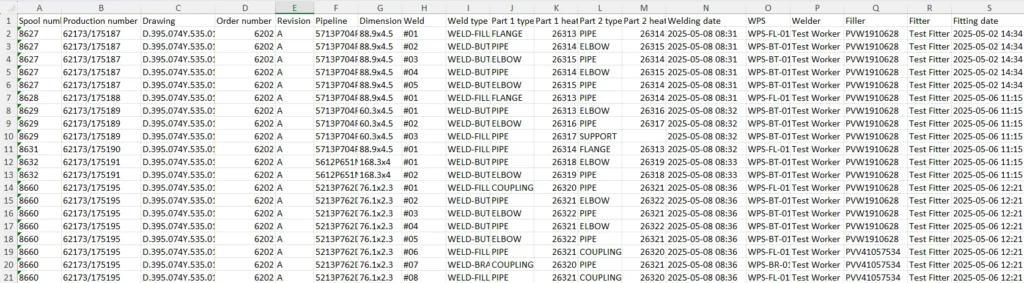

Clear input, ready-to-print output

Weld traceability reports are automatically generated in both PDF and Excel formats. These can be downloaded and printed immediately or retrieved later when the need arises, for example, during QA audits, customer reviews, or post-delivery troubleshooting. PipeCloud also integrates with WeldEye by Kemppi, making it easy to manage WPS data and synchronize traceability details across platforms.

Catch issues early and act fast

For example, if a filler batch is flagged as defective after installation, PipeCloud enables you to instantly locate every weld that used the same batch and schedule proactive inspections. If the root cause turns out to be a specific welder or process setting, the same logic applies: No digging through paper logs or spreadsheets, and no guesswork.

Improve quality, reduce risk, stay compliant

Welding traceability in PipeCloud gives you clarity, control, and confidence in your production process. It helps you meet compliance standards, reduce rework, and prevent avoidable failures, whether they show up on the shop floor or months later on-site.

Ready to see it in action?

Book a demo to explore how PipeCloud simplifies welding traceability, improves fabrication quality and much more.