Parsing spool PCFs in PipeCloud — turn CAD data into structured spool information automatically

PipeCloud’s PCF file parser allows pipe prefabricators to extract detailed CAD data from PCF or XML files and match it with spool drawing PDFs. The result is a complete, structured dataset that’s immediately usable for production planning, without the need for manual data entry.

The challenge: CAD data often goes unused

Many customers design their piping systems in 3D tools that can export structured Piping Component Files, also known as PCFs. However, these files are often overlooked. Customers might not realize they are useful, and suppliers may not ask for them. As a result, planners rely solely on spool drawings and miss out on valuable data like component details, welds, and geometry that already exist in the CAD model.

Without PCFs, planners spend more time interpreting drawings and retyping values that could have been imported automatically.

Upload and parse CAD data

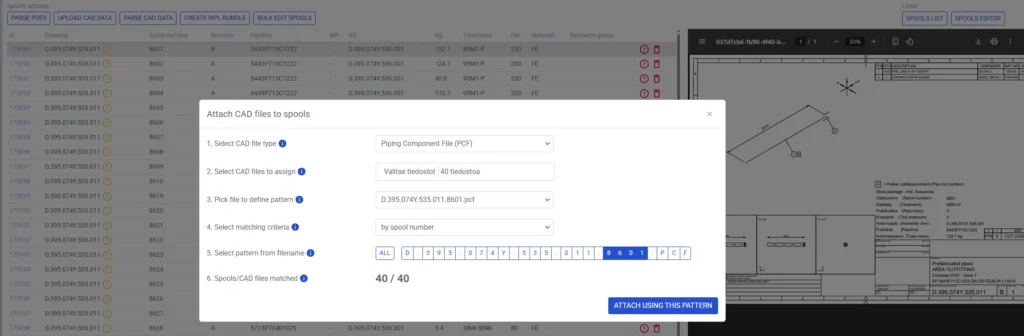

After importing and parsing spool PDFs, production planners can upload PCF or XML files and define a pattern to match each file with the correct spool. The pattern is usually based on the spool number found in the filename, but could also be something else. PipeCloud uses a company-specific input catalog to interpret each CAD file according to the file format that the CAD files adhere to, and extracts the relevant data.

With one click, the system then parses all PCF files and loads the spool content into the planning view.

What PipeCloud extracts from PCF files:

- Component hierarchy and spool structure

- Pipe sizes, wall thicknesses, and lengths

- Material classes, grades, and standards

- Weld types and weld locations

- End preps, bends, and cut-piece allowances

- Connection and coordinate information

- Pressure ratings and project metadata

- Project-specific attributes

The parsed content appears directly in the spool list, populating rest of the empty fields left after PDF parsing.

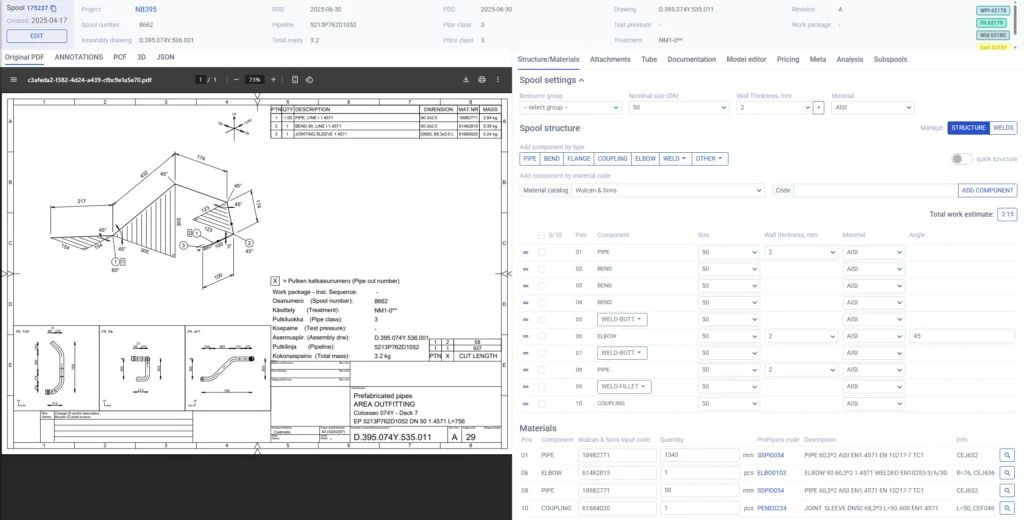

Combine drawing data and CAD content

PipeCloud links parsed PCF data with the data from the spool drawings. This automatically merges drawing-based and CAD-based information into a single, structured spool record. Once both PDF and PCF files are parsed, planners have everything they need in one place and can go straight into production planning, with no re-entry or manual merging needed.

Review and adjust spool data

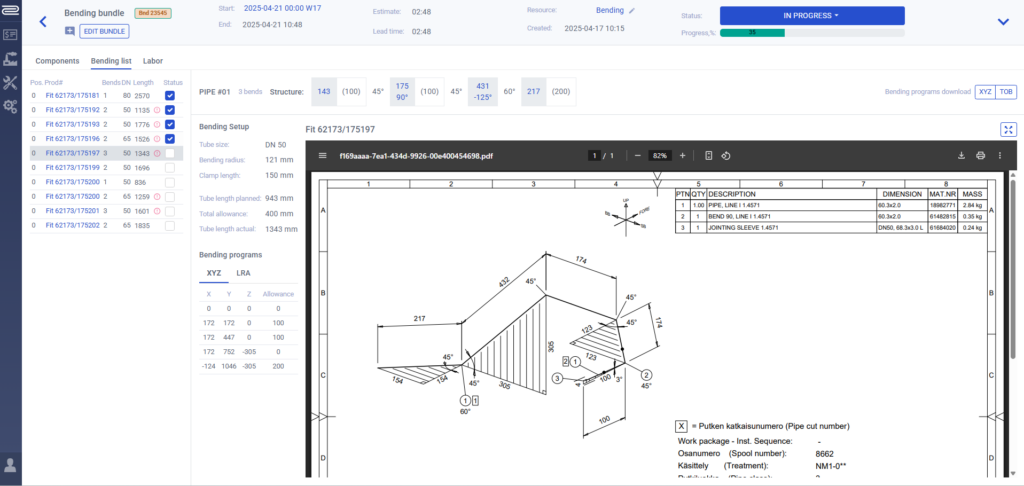

Once parsed, spool information is available across three tabs in the spool editor:

- Structure/Materials – Review and edit components and material data

- Welds – Add or auto-fill weld names and mark their locations

- Tube – Inspect or adjust geometry, end preps, and bending values

You can make changes manually when needed, and the system keeps track of all updates.

If you’re not using PCF yet

Even if your customers aren’t currently sending PCF files, chances are they can. Most 3D piping tools support PCF export, and these files can be delivered along with spool drawings. Once imported into PipeCloud, PCFs eliminate the need for duplicate data entry and make it much easier to build a structured digital workflow.

From parsing to planning

With both CAD and drawing data linked, PipeCloud creates a complete digital spool structure that contains all the data needed for production. This allows planners to move straight into production bundle creation, scheduling, and resource planning; all without scrappy spreadsheets or disconnected files.

Ready to see it in action?

Book a demo and explore how PipeCloud PCF parsing simplifies spool data handling, speeds up planning, and sets your production up for success.