Track progress and spent time in PipeCloud — see what’s happening, while it’s happening

PipeCloud gives you real-time visibility into production progress and actual time spent during pipe prefabrication. Every phase of pipe prefabrication is tracked and compared to estimated durations. You know exactly where things stand and where improvements are possible. For a complete shop floor overview, check out PipeCloud live factory view.

The challenge: No visibility, no control

Most pipe fabrication shops rely on paper, memory, or walking the shop floor to track how production is progressing. Delays are only noticed when it’s too late. Time spent on each phase is rarely measured, let alone compared to what was expected.

Often, the only available overview is a messy Excel file, hastily updated and quickly outdated. This makes it hard to:

- Spot bottlenecks before they cause disruption

- Understand how spool complexity affects throughput

- Know what’s working well and what needs fixing

Time estimates, real-time tracking, and full visibility

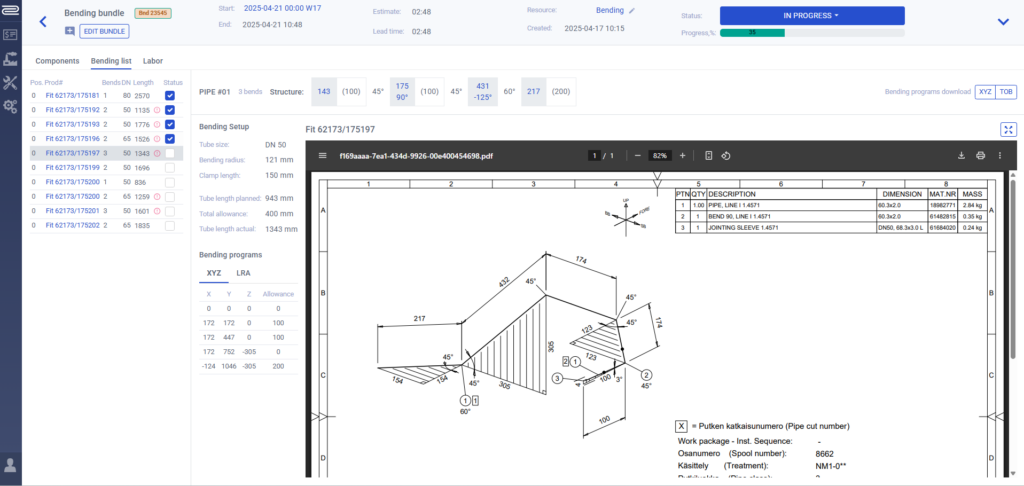

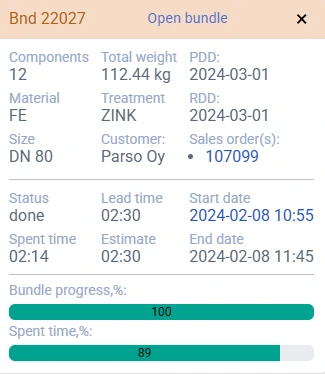

PipeCloud automatically calculates time estimates for every production phase based on spool content. Estimates take into account pipe sizes, materials, wall thickness, number and complexity of components, surface treatment, and other requirements. These estimates are grounded in industry averages and can be refined over time based on your actual data.

As work progresses:

- Workers log spool or bundle completion on tablets at each phase

- PipeCloud captures actual time spent and compares it to the estimate

- Managers and planners get real-time visibility into every active order

You can view progress at the level of a bundle of spools or individually, across all production phases. This makes it easy to manage shop floor operations, track delays, and make informed decisions before issues grow.

Planners can balance workloads between stations based on accurate lead time estimates and shop capacity. This also supports PipeCloud capacity planning, where resource constraints and deadlines can be aligned across parallel projects.

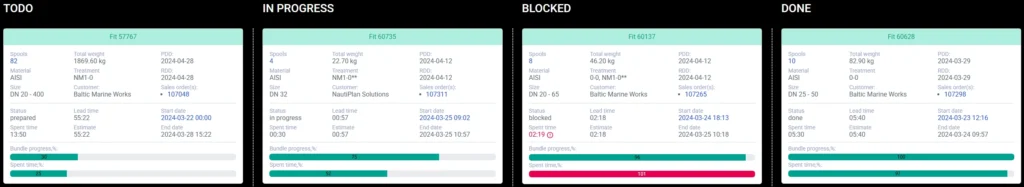

Supervisors get a live view of what’s ready, what’s in progress, and what’s blocked. They can verify at a glance whether cut pipes, materials, or components are in place before work begins — avoiding unnecessary stops.

Workers can also report issues directly through the system, giving supervisors the insight they need to act quickly and keep production moving.

How it helps in practice

Let’s say a bundle is moving slower than expected in the welding phase. With PipeCloud, the supervisor sees it immediately and can act. They might check for missing materials, reallocate labor, or flag the issue to the planner.

At the same time, actual time is being recorded. Over time, this data helps refine future estimates, identify recurring slowdowns, and highlight areas of strong performance.

If a task is delayed or only partially done, it can be reassigned to another worker without disrupting the workflow. All activity is logged and traceable, supporting process accountability and better communication with planners, designers, or customers.

For fast task coordination and a clear overview of production activity, progress and time tracking also forms the foundation for the PipeCloud Kanban view.

Clarity that drives improvement

Progress and time tracking in PipeCloud gives every team a clear picture:

- Workers see what’s expected and mark their progress easily

- Supervisors stay on top of shop floor status in real time

- Planners know if orders are on track to ship or need attention

This transparency helps reduce delays, improve delivery reliability, and build a more predictable production process. It also sets the foundation for continuous improvement based on facts rather than guesswork.

Ready to see it in action?

Book a demo and explore how PipeCloud gives you real-time progress tracking, performance insight, and clarity from spool to shipment.