Ensuring Quality with Welding Traceability in Piping Projects

Ensure quality and compliance in piping projects with welding traceability. Learn its importance, challenges, and modern solutions to streamline processes.

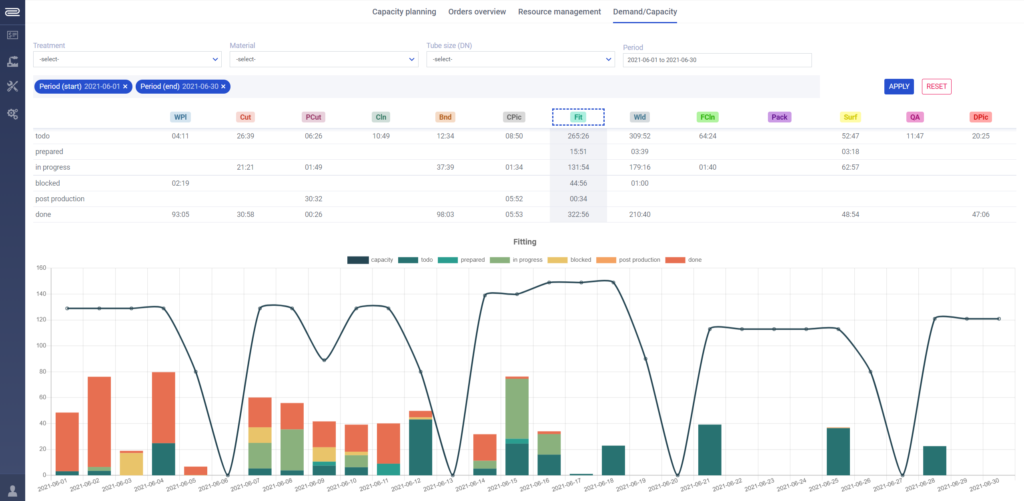

PipeCloud gives supervisors real-time visibility into work readiness, task progress, and shop floor communication — all in one connected system.

Supervisors need to stay on top of what’s ready, what’s in progress, and what’s blocked — often across dozens of parallel tasks. Verifying that all preconditions are in place before work starts, such as checking if pipes have been cut or components are available, typically requires manual checks and constant interruptions. When deadlines shift, it’s equally challenging to track who’s done what and reassign unfinished work efficiently. PipeCloud brings clarity to this complexity by giving supervisors real-time visibility into the production floor, so they can manage proactively instead of reactively.

Supervisors can verify that all prerequisites, including materials and prior work phases, are ready before a task is started — supported by features like the Kanban view.

Every item on the shop floor can be identified instantly through progress and time tracking: what it is, who worked on it, and what remains to be done.

Unfinished or delayed work can be reassigned or split between workers using tools like capacity planning to help balance workloads and keep production moving.

Workers can report blocking issues directly in the system, giving supervisors the insight they need to act quickly.

All actions are recorded, enriched with context, and preserved — reducing manual errors and supporting better feedback to customers or designers.

Your questions matter. Drop us a line anytime. We’ll get back with the details you need.

Ensure quality and compliance in piping projects with welding traceability. Learn its importance, challenges, and modern solutions to streamline processes.

Learn the complete pipe fabrication workflow, from design to assembly. Look into processes, components, best practices, and modern innovations in fabrication.

“You can easily see that all the preconditions are ready for fitting. PipeCloud shows you the status of all the previous work phases, so you don’t have to run around the factory with papers”