From Manual to Digital: Transforming Pipe Prefabrication and Traceability

We are at a crucial moment in history. A shift from oil and gas to hydrogen is on the horizon. Hydrogen is cleaner and more …

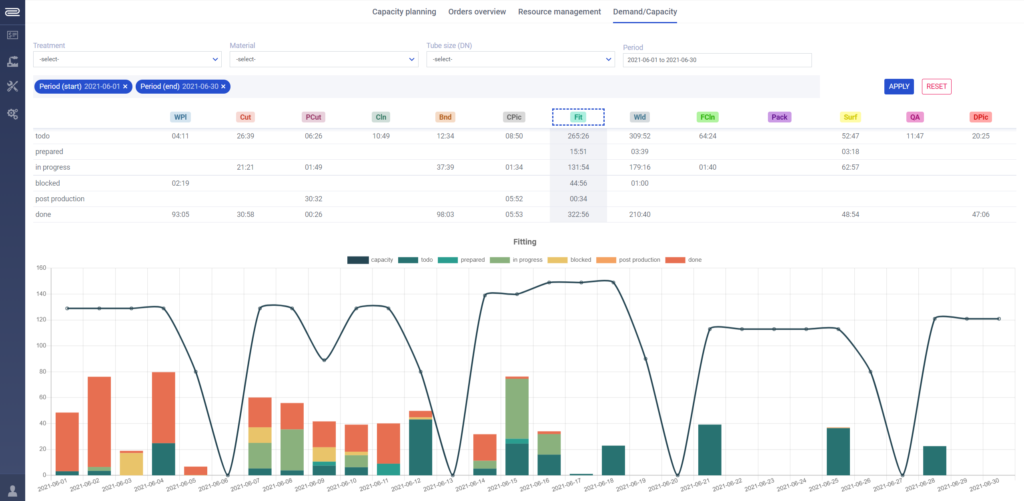

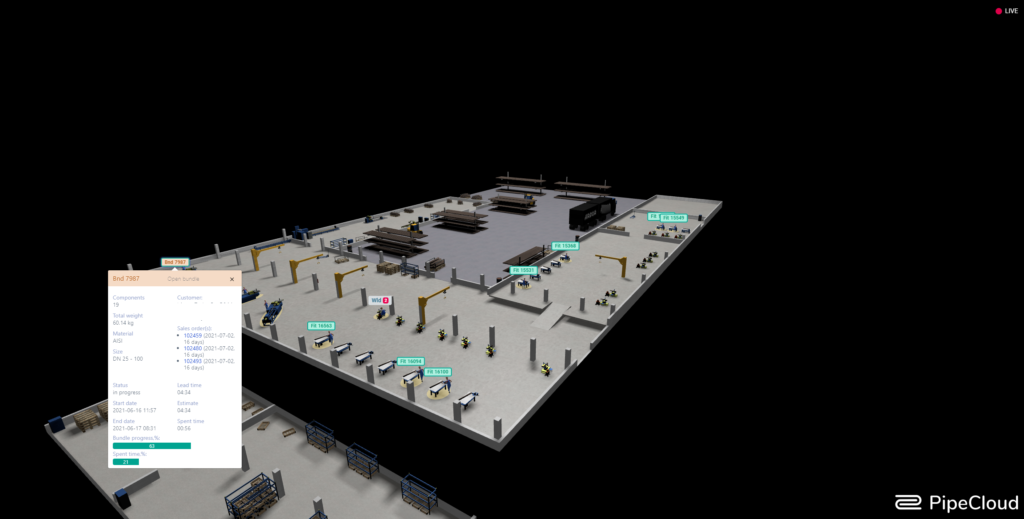

PipeCloud enhances management’s situational awareness by offering tools such as Capacity View, Kanban View, Sales Order View, and Live Factory View.

Whether it’s the Production Manager, Sales Manager, or CEO, decision-makers need real-time visibility into production capacity and output — wherever they are. Without the right tools, getting a clear overview often means time-consuming detective work or multiple phone calls.

PipeCloud solves this with features like the Kanban View, Live Factory View, Sales Order View, and Capacity/Demand View, making it easy to monitor performance, track KPIs, and make informed decisions.

Your questions matter. Drop us a line anytime. We’ll get back with the details you need.

We are at a crucial moment in history. A shift from oil and gas to hydrogen is on the horizon. Hydrogen is cleaner and more …

We are thrilled to announce that PipeCloud will be participating as exhibitors at the renowned Defence and Security Equipment International (DSEI) event in London. The …

“You can easily see that all the preconditions are ready for fitting. PipeCloud shows you the status of all the previous work phases, so you don’t have to run around the factory with papers”

PipeCloud has solved a genuine problem for industrial customers in a simple way that is easy to take into use, says the company’s new senior …

Digitalization of welding accelerates when the capability of the most intelligent welding machines is combined with the information produced by a unique manufacturing execution system …